1.Suitable width of sheet or coil: max1550 mm 2.Cleaning type:Brushing roll 3.Water temperature control:by control table or/Screen pad 4.Dry way:By fan

Basic specification for Polishing machine

| Cleaning and drying unit | 4 pcs Brushing roll for cleaning |

| Power | 20 KW |

| Dia meter of brushing roll | 150 mm |

| Maximum widht of material | 200-1550 mm |

| Thickness for stainless steel | 0.3-3 mm( Standard) |

| Feeding speed | 0-50 M/min for sheet or coil |

| Processing type | oil wet type |

Technical Parameter

1.Raw material:

a.Stainless steel sheet : 430,439,445,304,316,200 series

b.Sheet surface:2B and BA surface

c.Sheet width: 200-1550 mm. max sheet: 1300*4000mm/6000mm

d.thickness of sheet:0.3-3mm.

2.Finished product parameters:

Surface of stainless steel sheet: cleaning the surface of SS .

3.

Equipment Description:

Cleaning and Drying Machine:

1. Square tube welding frame, side plate thickness 22mm;

2. Clean in two Section, the first stage is equipped with oil grinding head. 0.4KW gear motor drives high-temperature silk brush cleaning, circulating water, hot water temperature can be adjusted;

3. Waterproof sheet metal parts and water tanks are made of 430 materials;

4. The transmission roller is covered with rubber, the diameter is 150mm, the roller surface length is 1600mm, and the worm gear reducer is driven by the universal joint sprocket chain;

5. Pressurized roller screw spring adjusts the pressure manually, including imported rubber, diameter 130mm, roller surface length 1300mm.

F. automatic inspection rack: square tube welding support frame, the feeding roller is made of stainless steel tube, and the rotation is flexible.

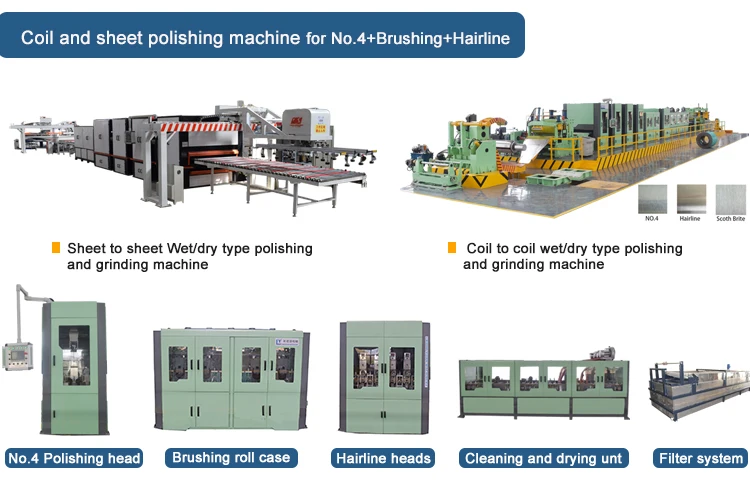

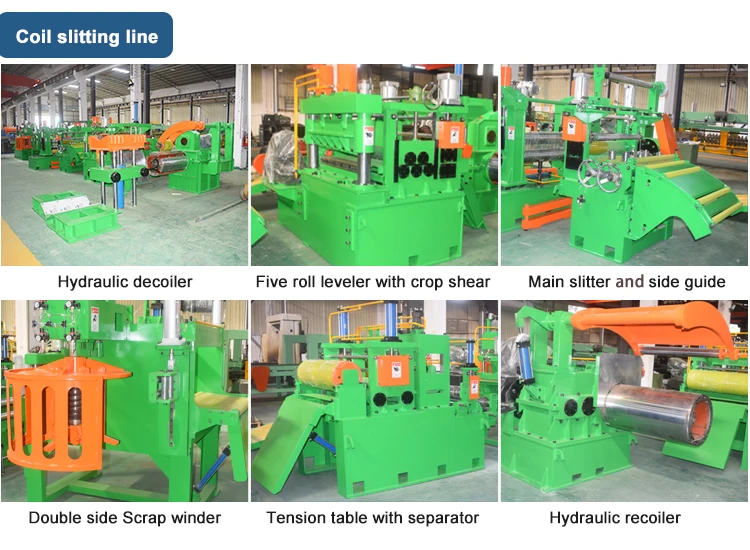

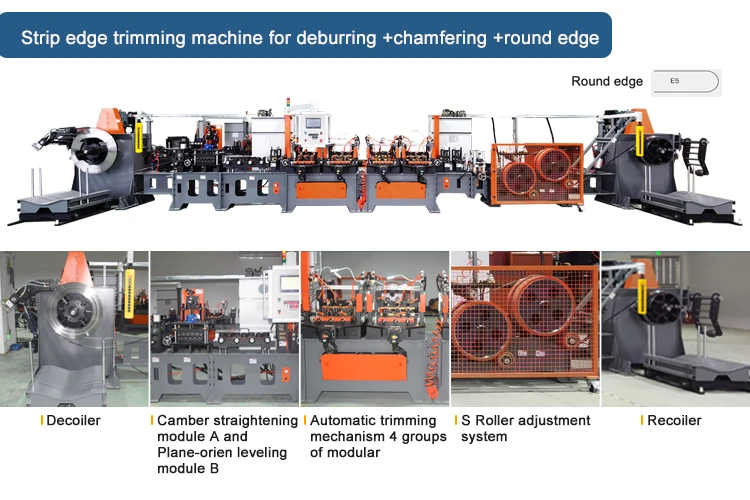

Q1: What kind of machine do you have ?

A1: We three type different machine line and accept customize

a. coil to coil wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

b. Sheet to sheet wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

c. Hi precision slitting line for cold roll for different width .

d. Cut to length (Stop shear and frying shear ) for cold roll

e. The strip edge trimming machine for deburring +Chamfering +round edge for different steel strip(from 5mm-300 mm)

Q2: How to visit your company?

Our company located in Foshan city ,Guangdong province of China , we can pick you up from Guangzhou Baiyun international airport or any other place in Guangdong province .

Q3:How long will you send the proposal and offer?

A3:We need you provide your material data and your requirement for machine,then we can give you offer within 2-3 days.

Q4: What is your payment term and lead time?

A4: We usually accept 30% deposit ( the strip edge trimming machine line need 50%), the balance must be paid before shippment ,or 70% is irrevocable LC at sight ; the lead time : we generally need about 90 days after getting deposit .

Q5: How to install the machine and the engineer fee,and warranty?

A5: We will send one or two engineer to install the machine in customer plant,the customer need bear the visa fee/flight ticket/accommodation during installation ,and give 80 usd subsidy to engineer; installation and training time : it usually need about 10-25 days with the cooperation from customer ,depend on the size of machine .

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China