THE PINNACLE OF PRECISION TRIMMINGENGINEERING EXCELLENCEAUTONOMOUS PRECISIONBESPOKE MACHINERY

Focus on Different kinds of Strip Edge trimming line for Deburring, Chamfering ,round edge , straight edge .Exporting to more than 10 countries and area.

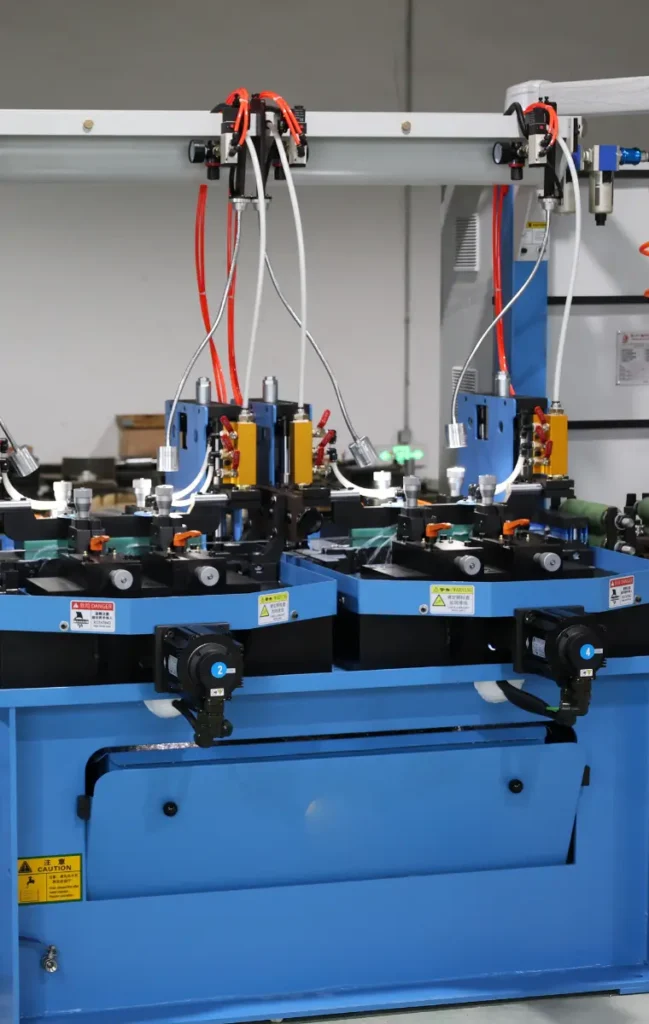

Modules Edge trimming combination

A highly flexible modular design, each individual module can be equipped with 3 to 6 precision blades. the machine can be configured with a customized combination of 1 to 4 modules

Intelligent strip trimming control system

Our self-developed control system ensures precise operational mastery, coordinating our flexible modular design...

About Glory(WXWY) Machinery

We Provide The Bespoke steel strip edge trimming machine for the Modern Industry

Flexible machinery configurations designed to integrate seamlessly into your existing production lines and specific material requirements.

About us

GLORY MACHINERY is a premier manufacturer specializing in the research, development, and production of high-performance Steel Belt Modular Trimming Machines.

Trimming Precision

Operational Efficiency

Client Satisfaction & Support

WHY CHOOSE OUR SOLUTIONS

The Advacned-Modular Steel Strip Edge Trimming Technology

With a passion for innovation. Our Steel Strip Modular Edge Trimming Machines are recognized worldwide for their robust build and unmatched accuracy. By integrating our self-developed control software, we provide a smart, scalable solution that grows with your production needs.”

Our Partner

Who We Are

Your Trusted Partner In Steel Strip Edge trimming Innovation

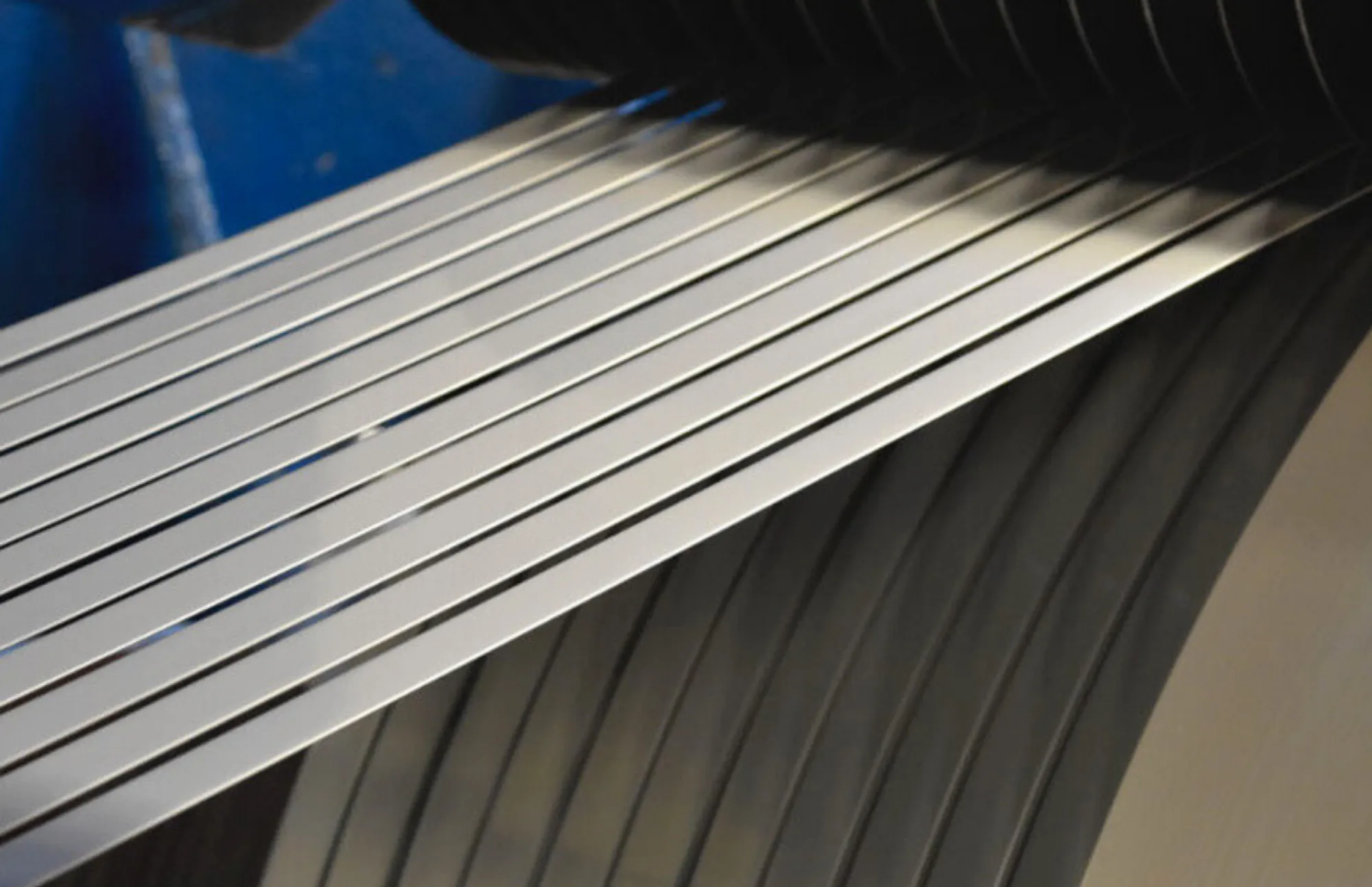

We redefine edge quality with our advanced modular trimming systems. From micron-level precision to seamless production integration, GLORY MACHINERY provides the cutting-edge tools needed to optimize your steel strip processing and maximize operational efficiency

- Immediate On-site Installation & Training

- Global Spare Parts Priority

- Lifetime Digital Support

The One Stop Solution for Your products

WHY PARTNER WITH US?

Extreme Accuracy

We engineering our trimming modules to achieve micron-level precision, ensuring the highest quality edge profiles for every steel belt.

20-Expert R&D Team

Backed by 20+ specialized engineers, we continuously innovate our self-developed control systems to stay ahead of industry standards.

Flexible Customization

Our unique modular design allows for 1-4 module configurations, perfectly adapting to your specific production line and material needs.

Proven Experience

With over 15 years in the global market, we bring deep industrial heritage and reliable engineering to every project.

Rapid Global Response

From on-site installation to 48-hour spare parts delivery, our global service network ensures your uptime is always protected.

On-site Installation & Training

We provide comprehensive on-site setup and professional operator training to ensure your team masters the machine for immediate productivity.

Applications

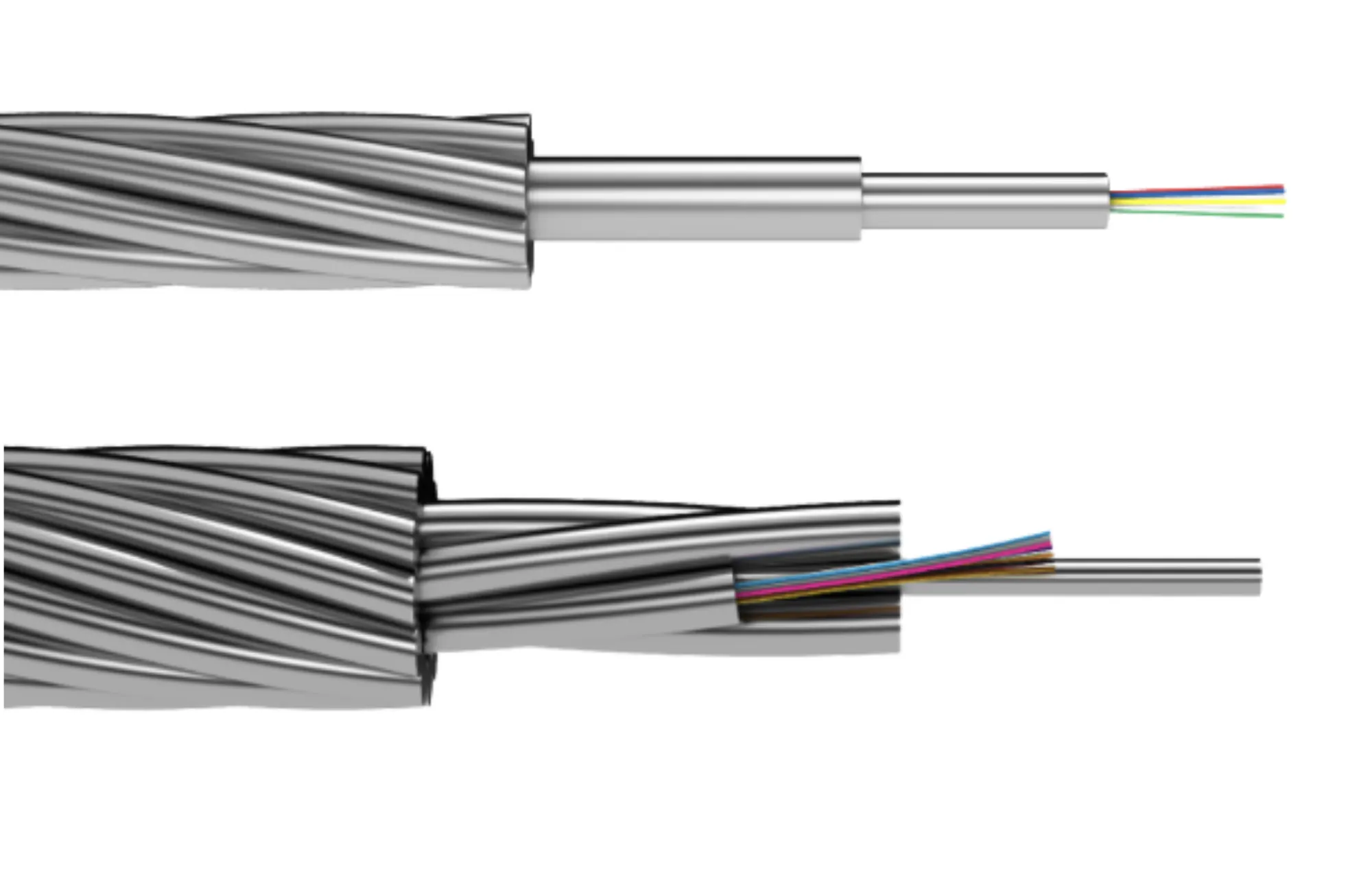

Cable Armoring & Shielding Solutions

"Ensuring burr-free edges for steel tapes used in cable armoring. Our precision trimming prevents damage to the inner insulation layer, guaranteeing structural integrity and long-term electrical safety."

Hose Clamps & Secure Fastening

"Delivering smooth, radiused edges for high-tension clamp bands (like CLAMP SECURE). Our technology eliminates sharp edges that could cut into hoses, ensuring premium quality for automotive and industrial fluid systems."

General Precision Metal Processing

"Versatile edge-conditioning solutions for various narrow-strip metal processing. From micron-level width control to customized edge profiles, we help processors meet the most stringent tolerance requirements for global export."

Automotive Parts Manufacturing

"Precise edge trimming for high-strength steel strips used in automotive seat tracks, reinforcements, and safety components. Our process ensures zero burrs to prevent stress concentration and meet the strict safety standards of the automotive supply chain."

Bi-Metal Band Saw Industry

"Optimized for the high-strength backing material of bi-metal band saws. We provide perfectly square and uniform edges, essential for high-quality electron beam welding and overall blade durability under extreme tension.

Architectural Facades & Decorative Metal Strips

"Achieving aesthetic perfection for exposed metal edges in architectural design. We provide consistent, polished-quality edges for stainless steel and copper strips used in premium interior decor and building facades, eliminating the need for manual secondary finishing."

Precision Tube Mill & Pipe Production

"Providing critical edge preparation for high-frequency induction welding. Our machinery ensures perfectly parallel strip edges and consistent width, significantly reducing welding defects and enhancing the burst pressure resistance of the finished pipes."

Transformer Core & Electrical Shielding

"Specialized edge conditioning for copper and aluminum foils used in transformer windings. Removing micro-burrs is critical to prevent insulation failure and localized overheating, ensuring the long-term reliability of power distribution equipment."

Global Trust & Recognition

Global Trust & Recognition

Hear what our global partners say about Glory(WXWY)’s precision trimming technology.

CEO from STELCO LIMITED

The modular design of GLORY’s trimming machine is a breakthrough for our cable shielding process. Each module’s ability to handle multiple blades with such micron-level accuracy has reduced our setup time and improved product consistency. From a process engineering perspective, their self-developed control system is intuitive and powerful. The 24/7 technical support they provide has been invaluable to our seamless operations."

Process Engineer from Incab LLC

"Having worked with various steel processing equipment for decades, I am deeply impressed by the robust engineering of GLORY’s modular trimming units. The vibration reduction design is exceptional, ensuring smooth edges even during high-speed continuous runs. Their 15 years of industry expertise are evident in every detail, from the blade life to the frame durability. It is professional-grade machinery that meets the most rigorous standards of Benxi Steel."

Senior Engineer from Benxi tool

Our News

Innovation & Performance Updates

From R&D breakthroughs to the launch of high-speed trimming solutions, explore how we empower steel manufacturers with cutting-edge equipment and smarter processing workflows.

Lion Dances and Red Envelopes: Foshan Glory(WXWY) Machinery Celebrates Grand Opening for 2026

LUNJIAO, SHUNDE – On February 24, 2026, the air in the Lunjiao industrial hub of Shunde was filled with...

Debuts Next-Gen Steel Strip Trimming Machine to Turkey

Glory (WXWY) Debuts Next-Gen Steel Strip Trimming Machine in Istanbul, Turkey FOSHAN, CHINA / ISTANBUL, TURKEY – June 10,...

As a leader in the steel industry in India, we demand equipment that combines high efficiency with absolute reliability. GLORY MACHINERY’s modular trimming solution has significantly optimized our production line since its installation. The precision and stability of their machines have exceeded our expectations, and their commitment to service makes them a trusted long-term partner for STELCO LIMITED. A truly strategic investment for our growth."