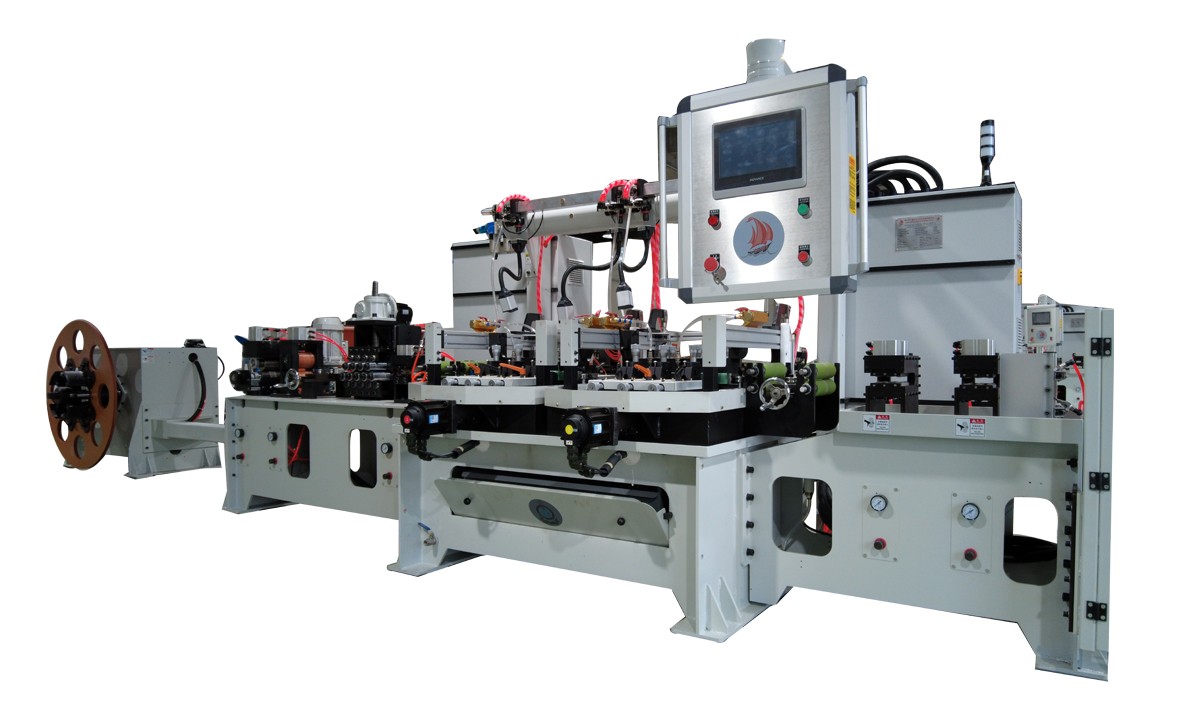

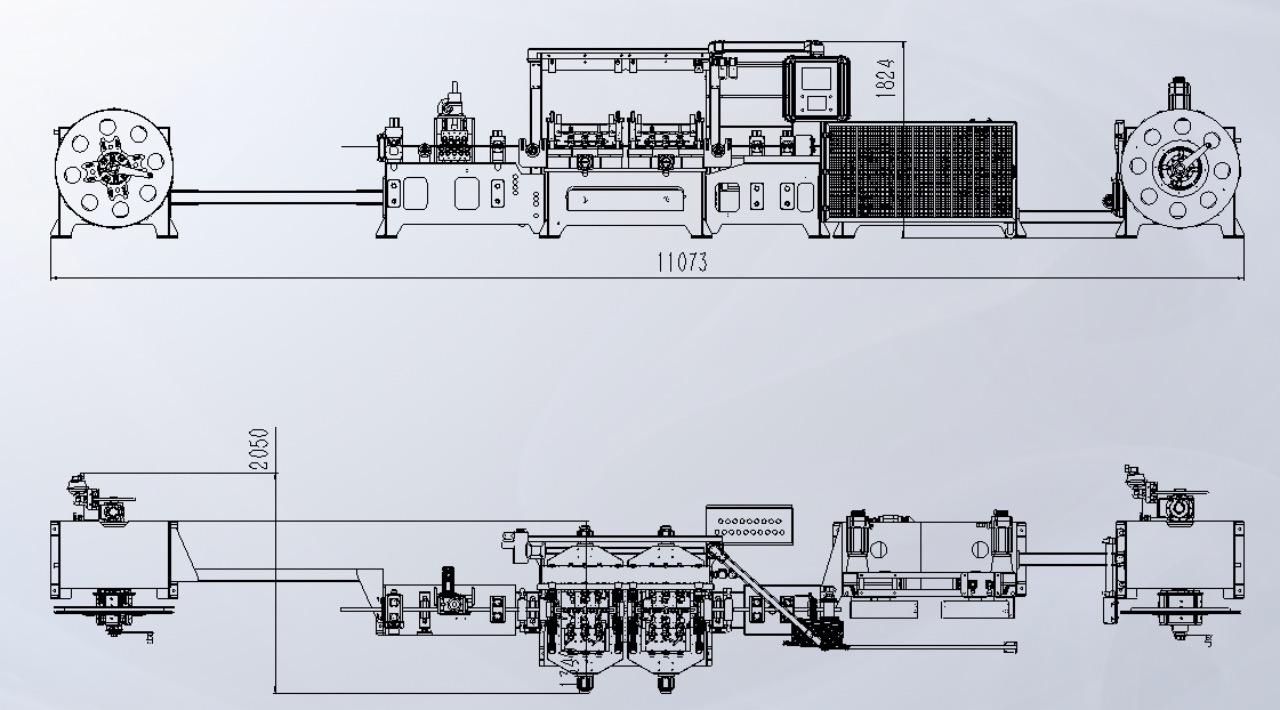

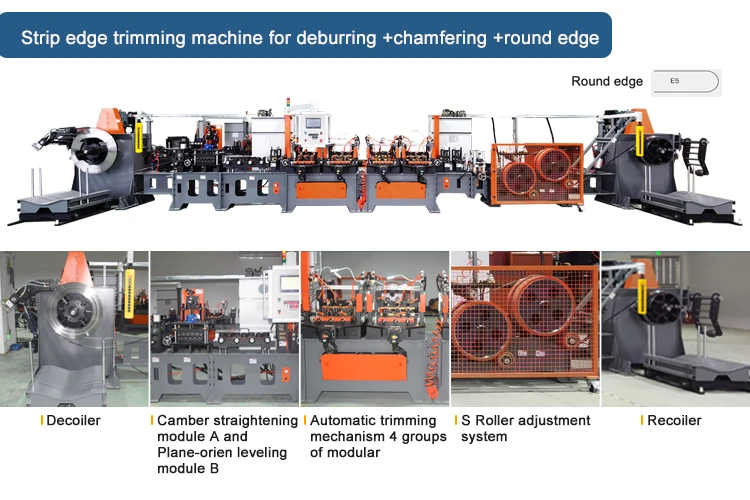

1.Trimming type for edge:deburring /chamfering /round edge 2.The material of strip:all kind of metal 3.strip width:10 mm-max 80 mm 4.thickness:0.5-2 mm 5.Speed of machine:0-130m/min 6.Total power:24 KW 7.Cooling:air and water 8.Knives for trimming:6 pcs ,max 12 pcs 9.Occupied area:W11.0*D1.5*H1.6 M

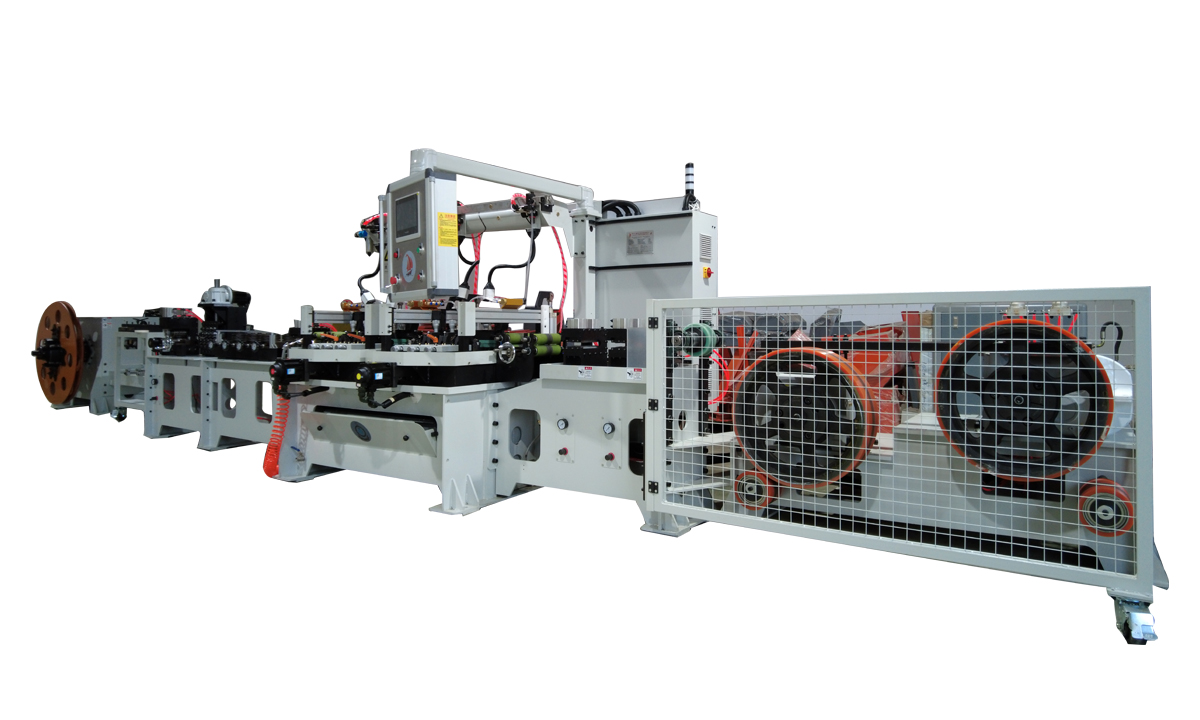

Basic specification for Strip edge trimming machine

Two group of automatic modular steel strip edge trimming machine production lines--combined price | ||||||

No. | Name | Model | Quantity | Unit Price/Fob Shenzhen or Nansha | Total Amount | Remark |

Two group automatic strip trimming machine | WXQB-2ZZD-CX | 1 set | 1*40HQ | |||

The components of the whole machine line are as follows: | ||||||

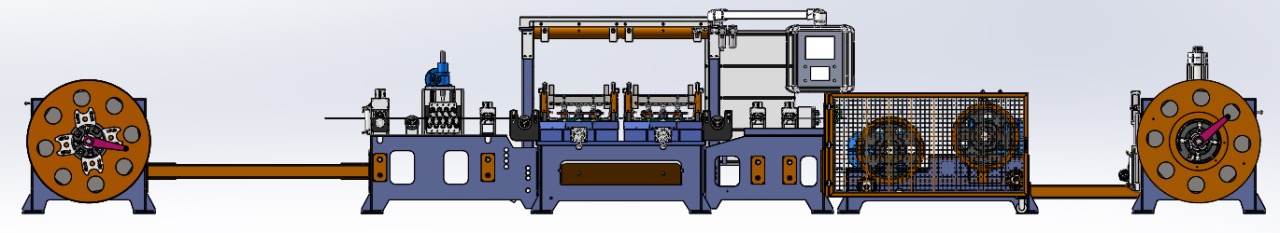

1 | Recoiler | WXSJ-400/1200GR89-186Y11K |

1 Pcs

| The maximum load-bearing capacity is 300KG, hand-operated mechanical diameter reduction, servo drive, including rewind and brake functions, the inner baffle is fixed, the outer baffle is retained, the guide roller is changed to a vertically adjustable structure, the winding and clamping mechanism is provided by the user. the design of. | ||

2 | Strip tension S-roll adjustment system | WXSG-GFAF87Y75P2 | 1Pcs | Dual servo motors are synchronously driven, including rewind function. | ||

3 | Limiting strip on center device 3 | 1 pcs | Limiting strip on center device 1 | |||

Cleaning strip unit 2 | 1 pcs | it has 2 groups for brushing +one group air cleaning | ||||

4 | Metal strip automatic trimming mechanism - 2 groups of modular | QB-ZD2Z-3/6-6/6 | 1PCS | Servo automatically advances/retracts Knives. with water or air cooling , with water inspection system | ||

5 | Limit strip on center device 2 | 1 pcs | ||||

6 | Cleaning strip unit | 1 pcs | ||||

7 | Plane Guide Leveling Module B-F Mechanism | WXXP-40Q-10H | 1 PCS | Thickness 0.5-1.5MM, maximum width 80MM, main function is to prevent blade damage caused by bending of the material head, servo drive. | ||

8 | Limiting strip on center device 1 | 1 pcs | ||||

9 | Automatic feedging unit | |||||

10 | Speed test and signal feedback system | 1 pcs | ||||

11 | Decoiler | WXKJ-400/1200GR77Y40 | 1 PCS | The maximum load-bearing capacity is 300KG, manual mechanical diameter reduction, servo drive, including rewind and brake functions. | ||

12 | AK-2 group control system | AK-2Z-ZD |

1PCS | Unit control system | ||

13 | Intelligent strip trimming central control system-HMI | V1.0 | ||||

Fob Shenzhen | ||||||

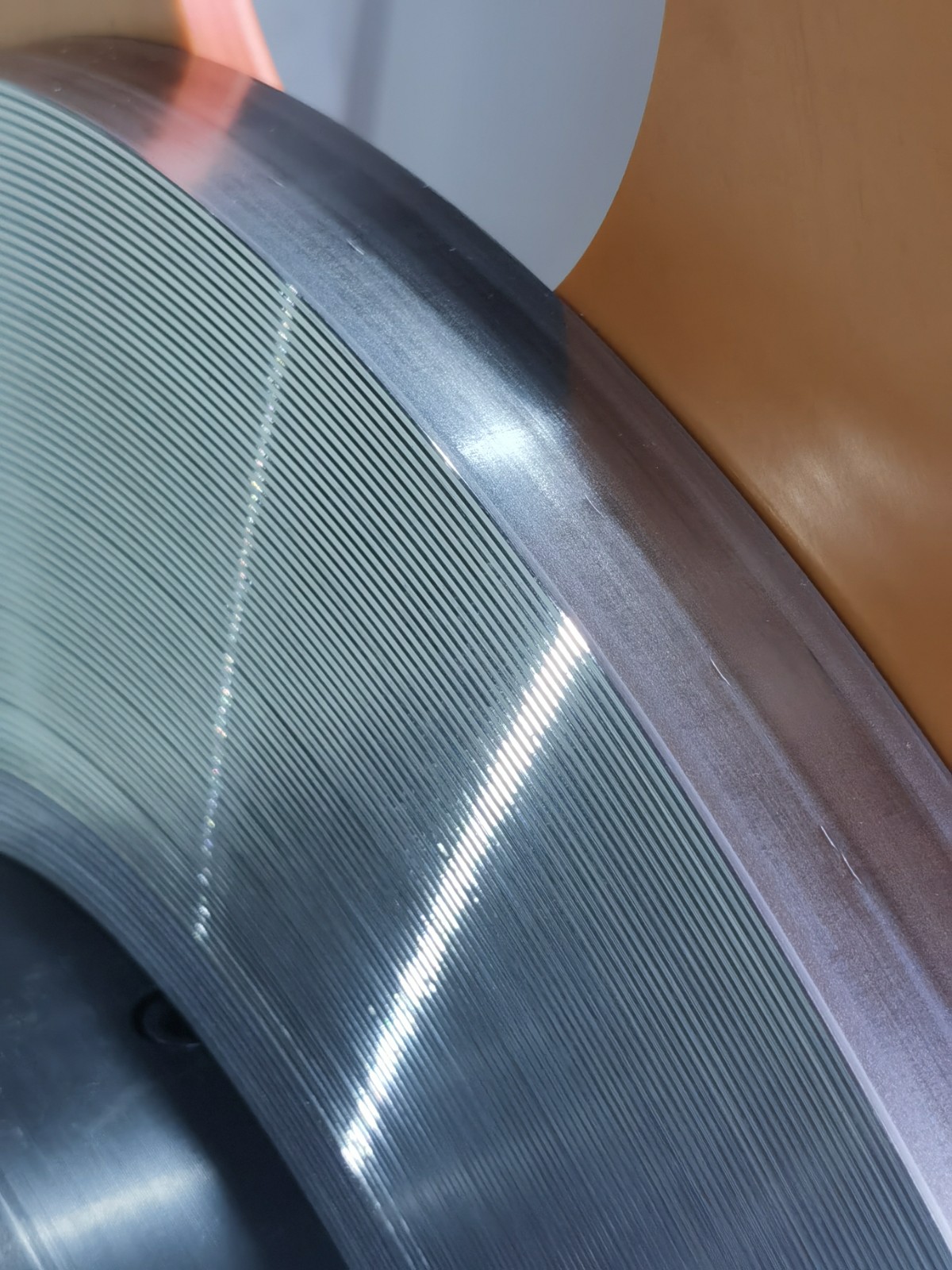

Equipment manufacturing process and parameters:Hardened and tempered high carbon steel strips | ||||||

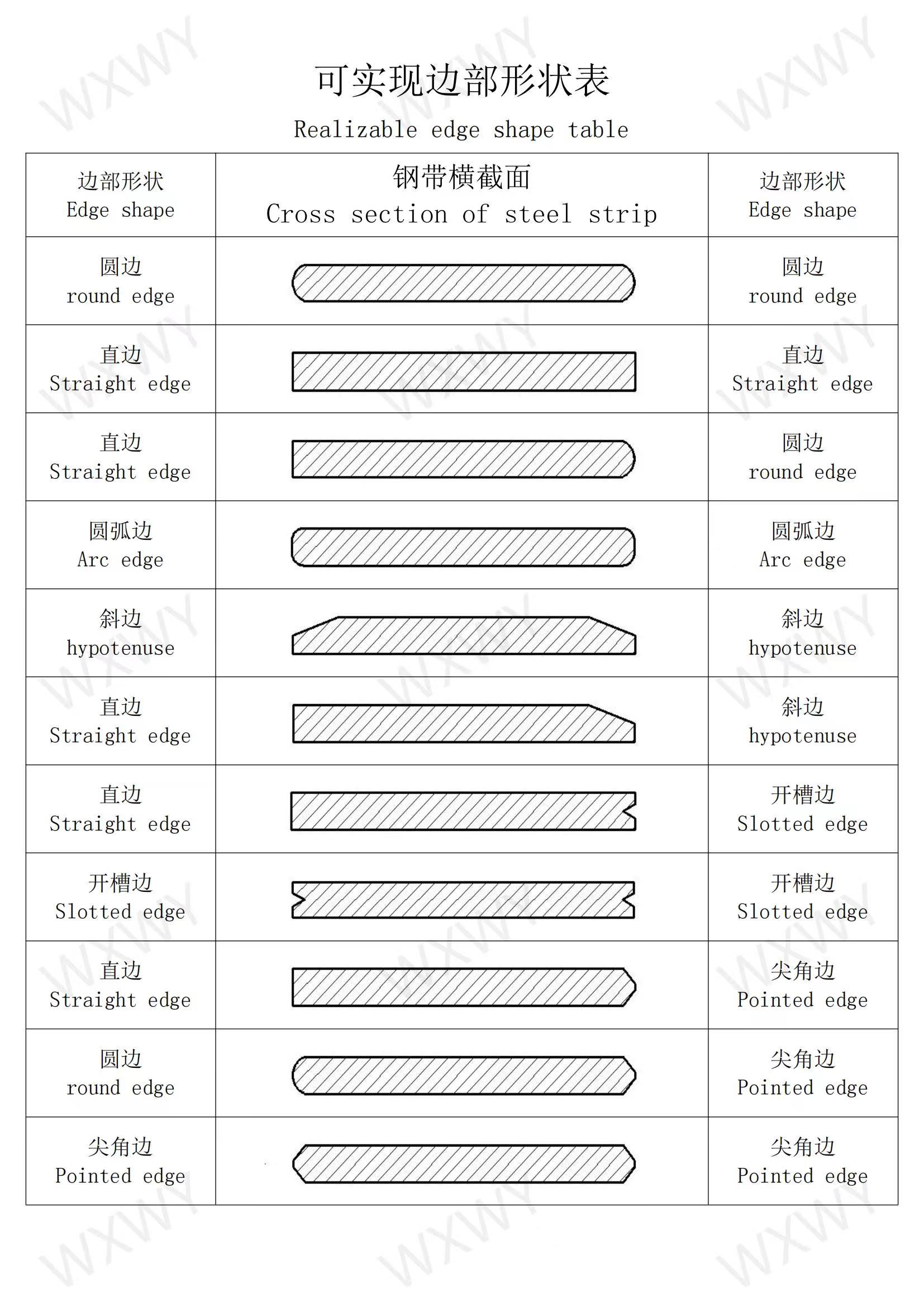

Strip material: Hardened and tempered High carbon steel strips, Cold roll strip ,Stanless steel strip and son on Tensile strength : 1000-1600N/mm² Width of strip range : 10-80mm Thickness: 0.3-1.5 mm Speed for trimming strip : 0-130m/min adjustable speed, strip trimming speed depends on material characteristics and trimming edge effect requirements Electricity : 380V,50Hz,DS (According to customer requirement) Controller voltage : 220V,50Hz,WS The electromagnetic valve : 24V-GS Direction : from Left to Right. Occupied area :W11.0*D1.5*H1.6 M Working height for trimming strip: 800- 1000mm Color: P-7503 Industrial white Cooling type :The latest automatic coolant supply system, liquid cooling (360° adjustable nozzle) Strip size: Inner Idia: 400mm±20,Max OD:1200mm。 Knives for trimming:Each group can be equipped with 3 or 6 trimming tools, up to 12 trimming tools can be transferred Scrap collection: With drawer type scrap collection box Trimming tool(blade): The trimming tool adopts general-purpose carbide blades and round-edged customized carbide blades.The angle of the edge or slotting is required. The blade seat can be rotated to adjust the angle. The method of trimming or slotting is Gradually feed type. Trimming shape: Steel strip edge deburring, chamfering, flat end or rounded edge. Other matters: According to design and technical needs and market product supply, Supplier can make adjustments to the above-mentioned equipment accessories Make changes to the brand and structure of the company without prior notice to Customer. | ||||||

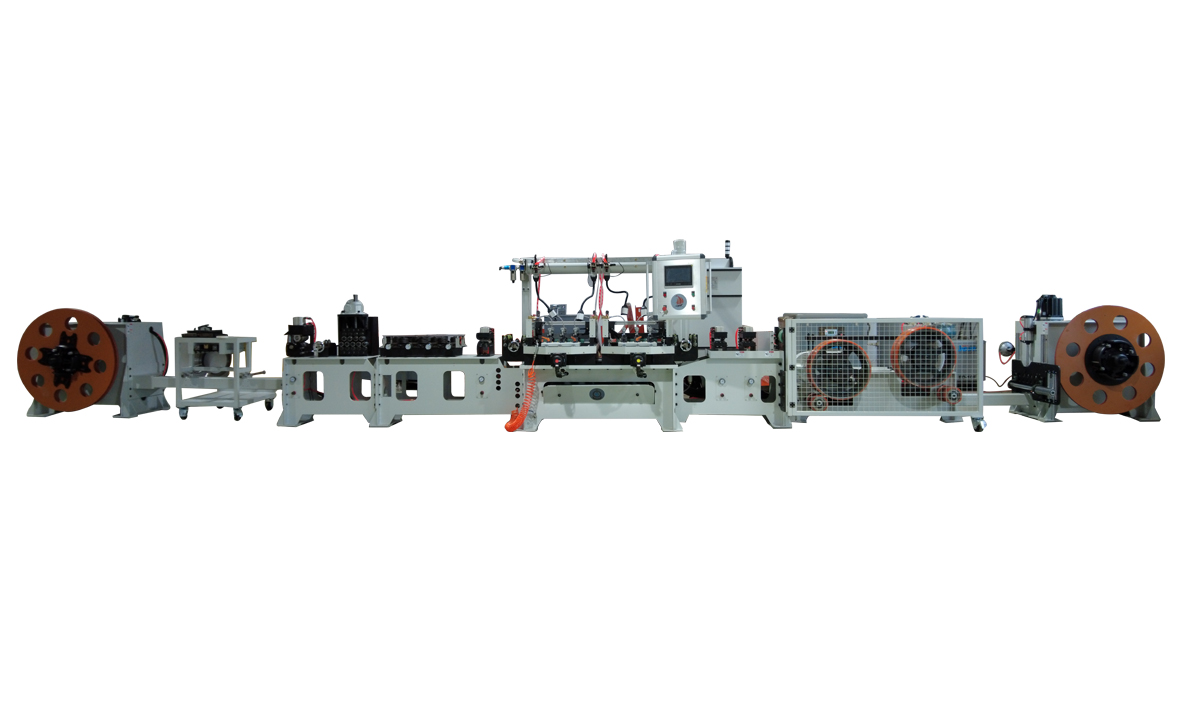

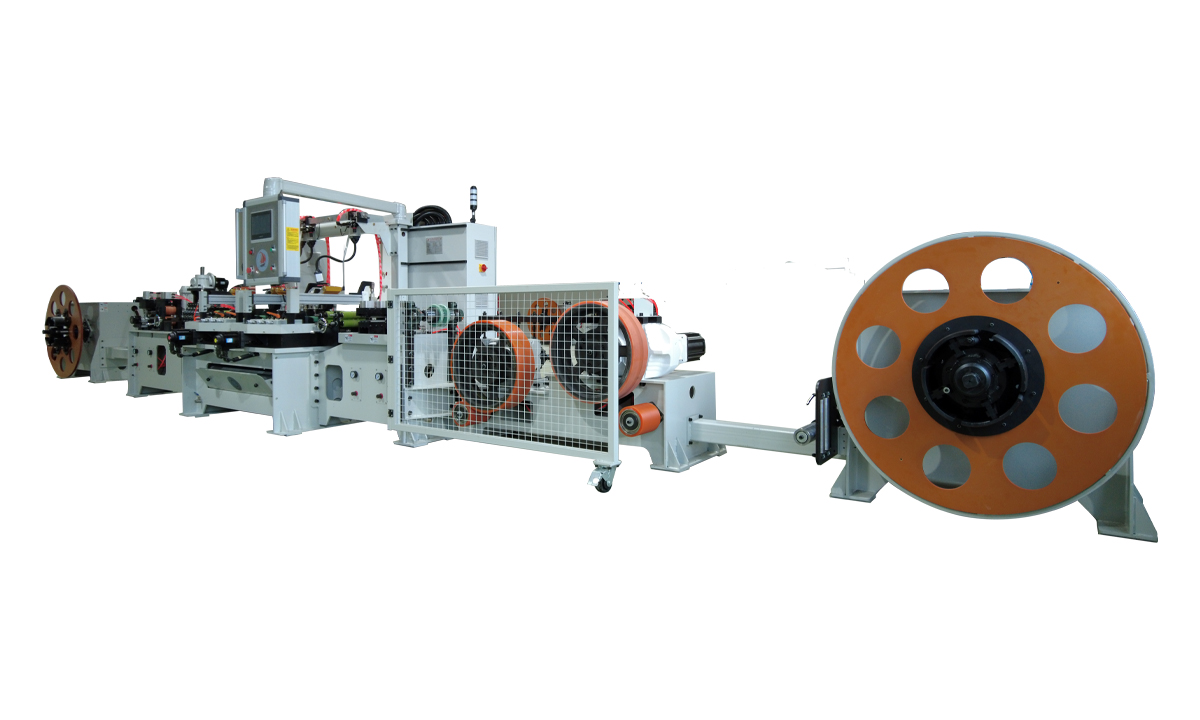

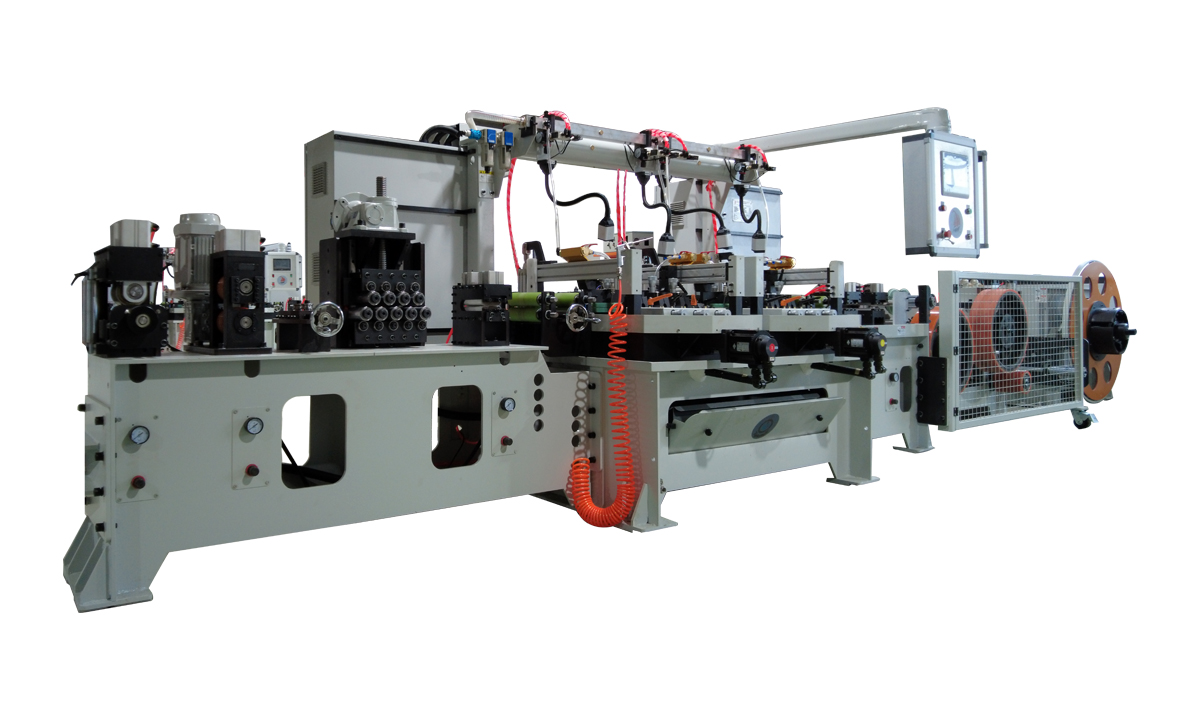

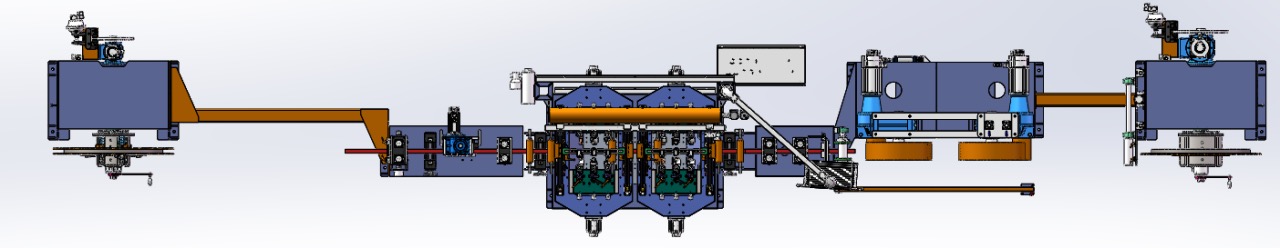

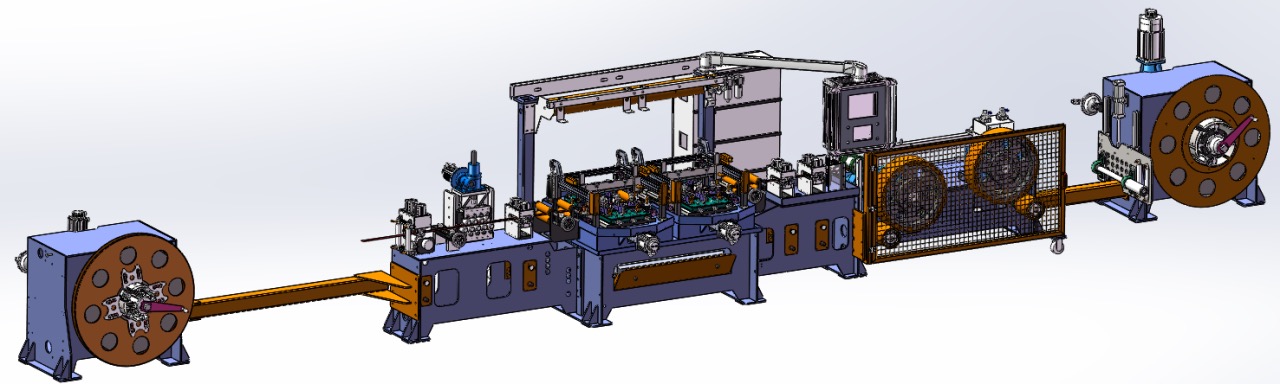

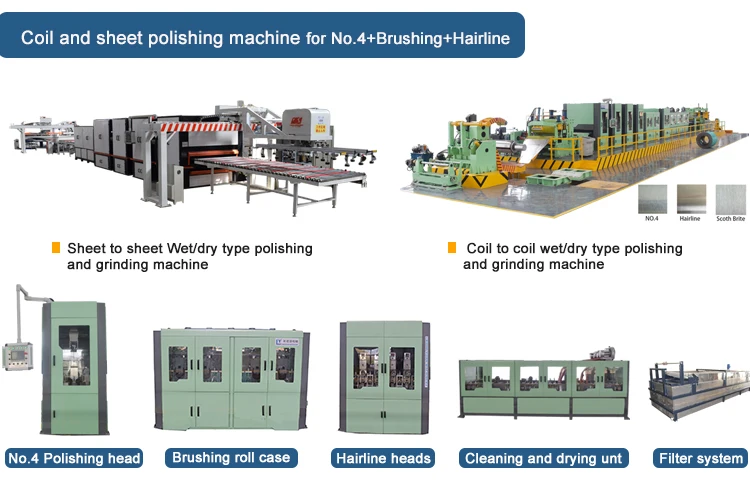

3D renderings of the equipment for reference :(The layout in the following figure is for reference only, and is not intended to describe the final device shape in this solution)

<span data-mce-style="margin: 0px; padding: 0px; border: 0px; font-style: inherit; font-weight: inherit; font-size: inherit; line-height: 27px; font-family: Calibri; vertical-align: baseline;" style="line-height: 27px; margin: 0px; padding: 0px; border: 0px; font-

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China