Place of Origin:Guangdong, China Condition :New Machinery Test Report:Provided Marketing Type: Hot Product 2024 Warranty of core components :1 years Core Components: PLC, Bearing, Gearbox, Motor, Gear Power (kW): 360 Weight (KG): 45000 Key Selling Points: Long Service Life Warranty: 1 years Brand Name: Glory Packaging and delivery Port Shenzhen/Nansha Supply Ability 5 Set/Sets per Month

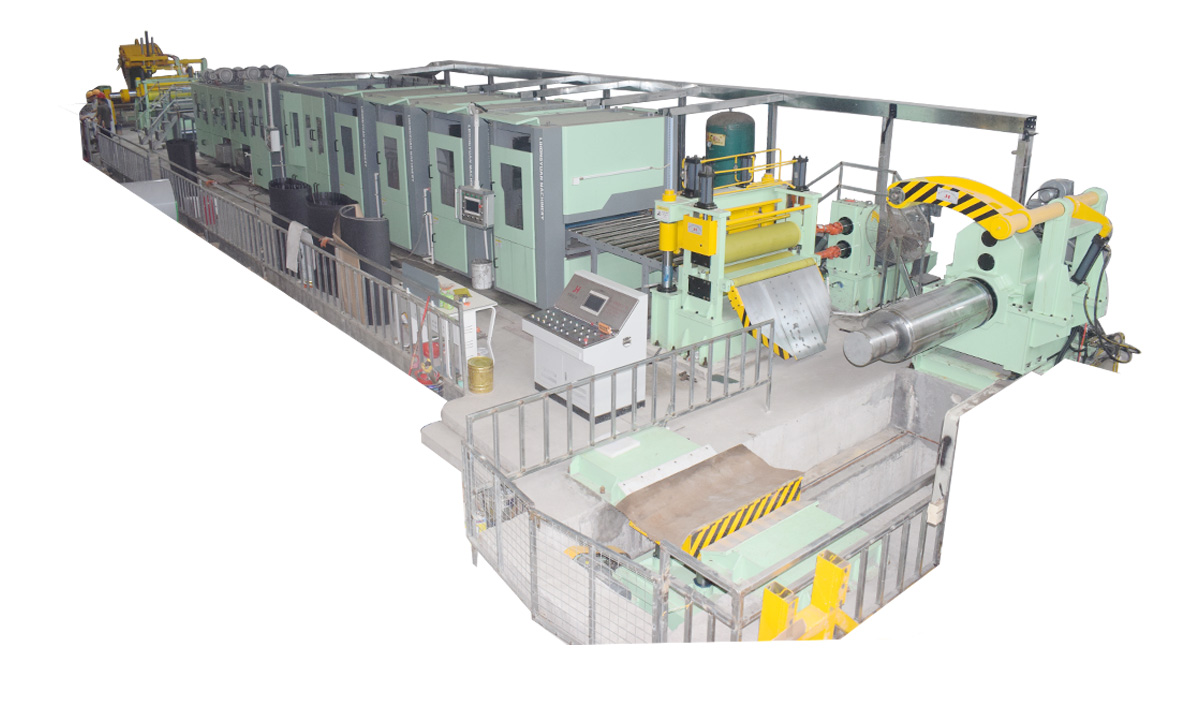

1300 wet oil type Coil to coil Polishing and grinding machine for NO.4+Brushing +Hairline

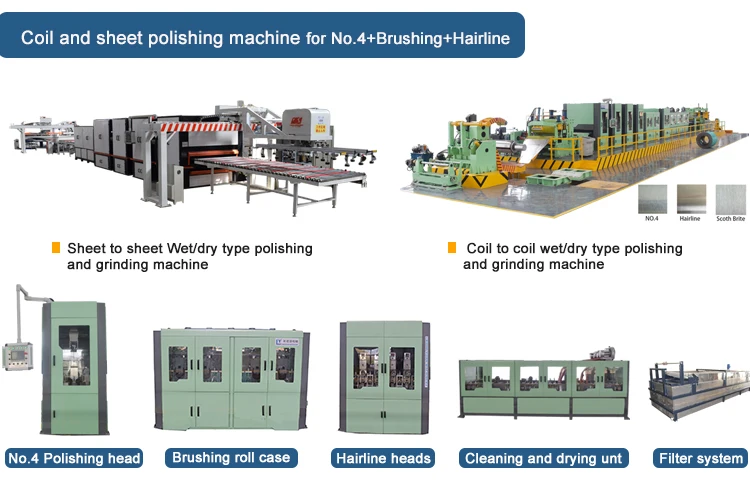

Basic specification for Polishing machine

| Polishing name | No.4 | Brushing roll | Hairline |

| Speed of Abrasive belt | 2000-3000 r/Min | 0.35m/min | |

| No. of polishing heads/roll | 4 grinding heads | 4 pcs rolls | 4 grinding heads |

| Power | 40KW*4+3KW transfer motor | 7.5*3 KW*4 KW transfer motor | 0.55 KW*3 Transfer Drive Motor |

| Abrasive belt length | perimeter 2620*1280 mm | Dia 300 mm | perimeter 2620*1280 mm |

| Maximum widht of material | 1250 mm | 1250 mm | 1250 mm |

| Thickness for stainless steel | 0.3-3 mm( Standard) | ||

| Feeding speed | 0-50 M/min | ||

| Processing type | oil wet type | ||

| Cleaning and drying | controlling hot water clean and fan drying | ||

| Filter system | use paper belt filte ,so the water can be recyled | ||

Technical Parameter

1.Raw material:

a.Stainless steel coil: 430,439,445,304,316,200 series

b. Coil surface:2B and BA surface

c.Coil Data: ID:490-508 MM, OD:≤φ1600mm. width:200-1250 mm. max coil weight:15 MT

d.thickness of sheet:0.3-3 .0 mm.

2.Finished product parameters:

Surface of stainless steel coil:NO.4 . (dependiing grit of abrasive belt 120#/150#/180# grit)+Brushing +Hairline

Coil Data: ID:508 MM, OD:≤φ1600mm. width:200-1250 mm. max coil weight:15 MT

3.Equipment parameters:

a.Speed:0-50M/min b.Power: About 386KW (Decoiler +recoiler are 170KW, Polishing machine is 40*4+7.5*3+10+25+=145KW), c.Operator: 1 technician and 2-3 workers.d.Height of working: 1000 mm. e.Space: W25*D6 M. f.Voltage:380V/ 3phrase/50 HZ(depend on customer requirment). g.Grinding Type:Wet oil type .h.PLC/HMI:Siemens

4.Equipment component

1..Decoiler +loading car /2.pre tenstion table with crop shear / 3.4 case for No.4 Polishing heads; /4. one case of 4 brushing heads /5.one case of 4 hairline heads/6.Clean and drying Unit/7. Platform for inspection/8. Laminating machine /9. Tention table with guiding roll /10. Recoiler +Assistant device for recoiler+EPC system +unloading car /11.paper decoiler /12.Paper filter Filter System/13.Simens PLC with control table System/14.Hydraulic System

Direction:From to (The operator faces the machine , feeding coil from)

Q1: What kind of machine do you have ?

A1: We three type different machine line and accept customize

a. coil to coil wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

b. Sheet to sheet wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

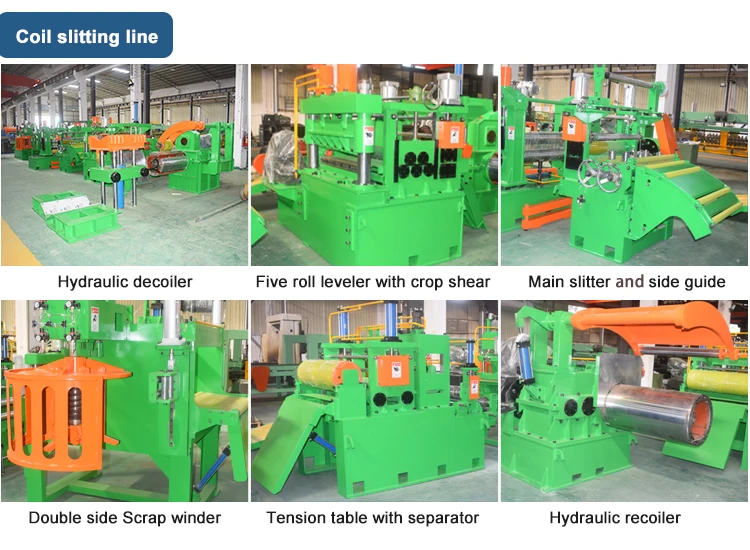

c. Hi precision slitting line for cold roll for different width .

d. Cut to length (Stop shear and frying shear ) for cold roll

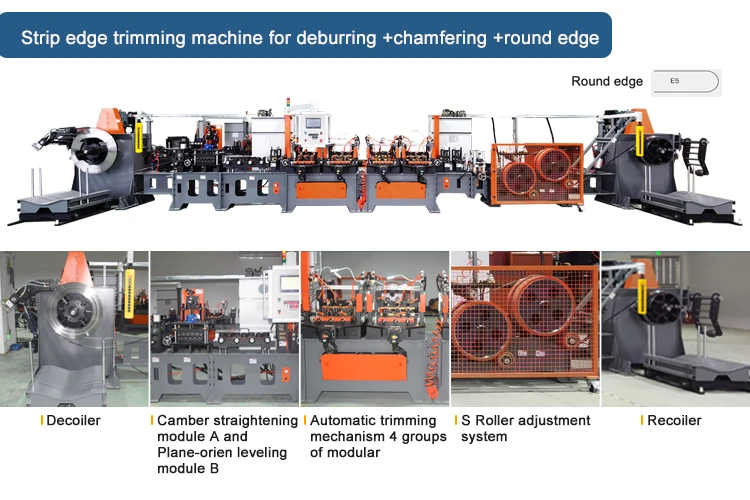

e. The strip edge trimming machine for deburring +Chamfering +round edge for different steel strip(from 5mm-300 mm)

Q2: How to visit your company?

Our company located in Foshan city ,Guangdong province of China , we can pick you up from Guangzhou Baiyun international airport or any other place in Guangdong province .

Q3:How long will you send the proposal and offer?

A3:We need you provide your material data and your requirement for machine,then we can give you offer within 2-3 days.

Q4: What is your payment term and lead time?

A4: We usually accept 30% deposit ( the strip edge trimming machine line need 50%), the balance must be paid before shippment ,or 70% is irrevocable LC at sight ; the lead time : we generally need about 90 days after getting deposit .

Q5: How to install the machine and the engineer fee,and warranty?

A5: We will send one or two engineer to install the machine in customer plant,the customer need bear the visa fee/flight ticket/accommodation during installation ,and give 80 usd subsidy to engineer; installation and training time : it usually need about 10-25 days with the cooperation from customer ,depend on the size of machine .

Contace person : Mike Chen Mob/Whatsapp:86 15815989367

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China