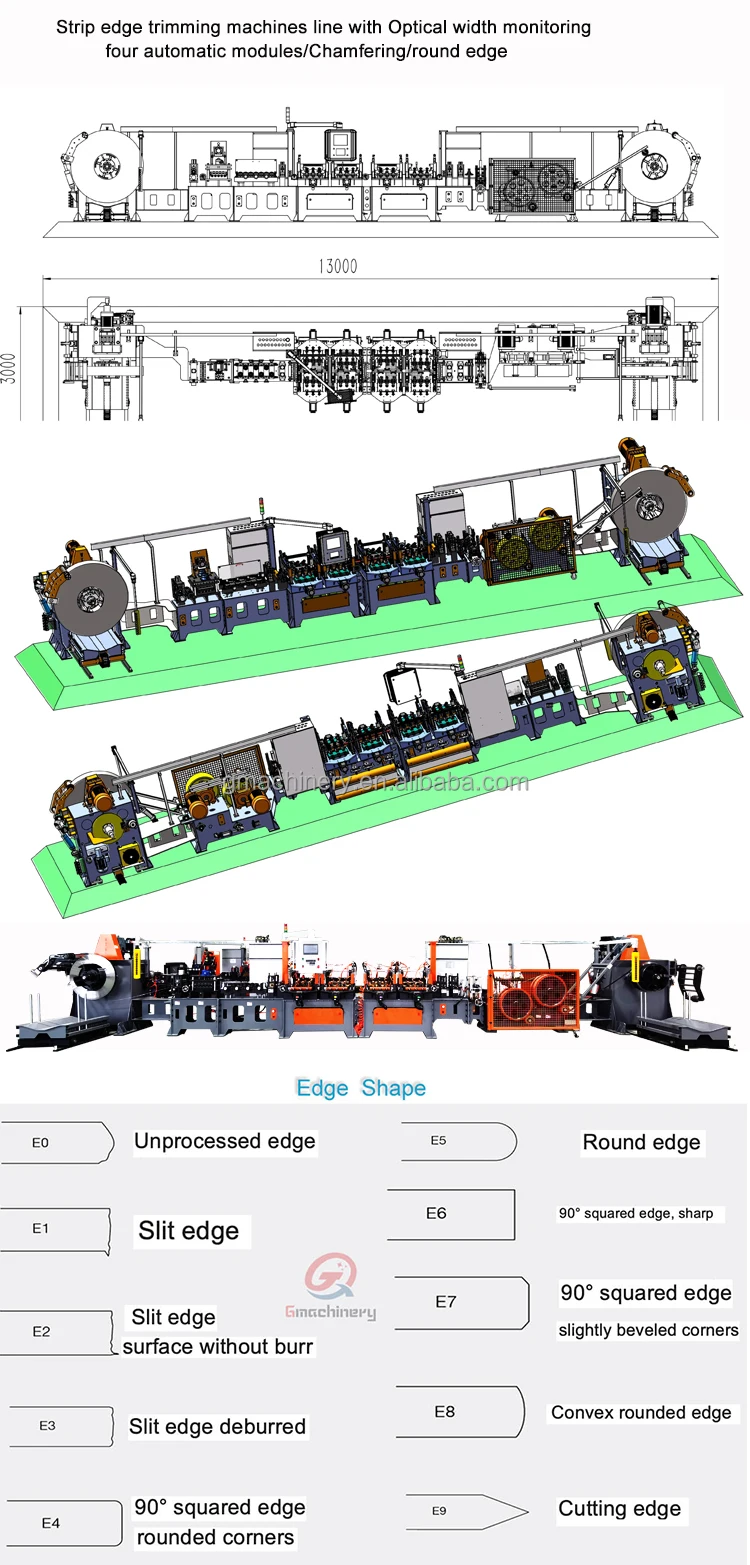

1.Trimming type for edge:deburring /chamfering /round edge 2.The material of strip:all kind of metal 3.strip width:10 mm-max 170 mm 4.thickness:0.2-2 mm 5.Speed of machine:0-150m/min 6.Total power:50.5 KW 7.Cooling:air and water 8.Knives for trimming:12 pcs ,max 24 pcs 9.width automatic monitoring system:Keyence from Japan 10.Occupied area:W13.0*D1.5*H1.6 M

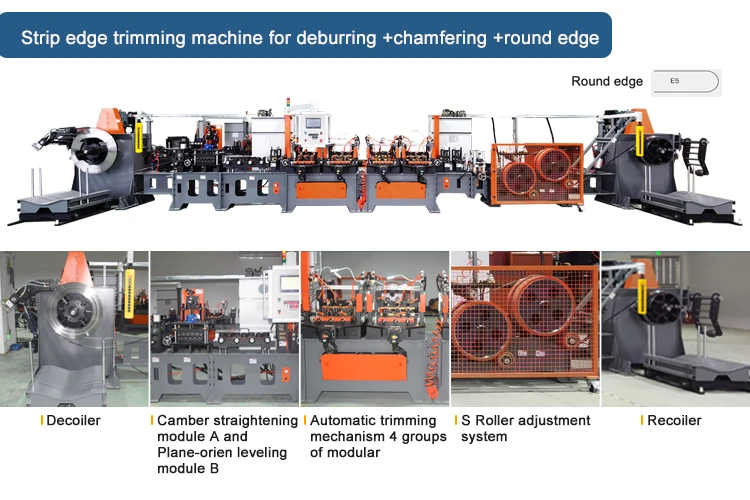

Basic specification for Strip edge trimming machine

Coil four groups of automatic modular Strip edge trimming line with Optical width monitoring

Technical Parameter

1.Raw material:

a. material: cold rolled strip,carbon steel strip ,Stainless steel strip and so on

b. edge : just be slited from slittng line .

c.Coil Data: ID:400-500 MM, OD:≤φ1200mm. width:10-180 mm. max coil weight:500kg-1000KG

d.thickness of sheet:0.2-2.0 mm.

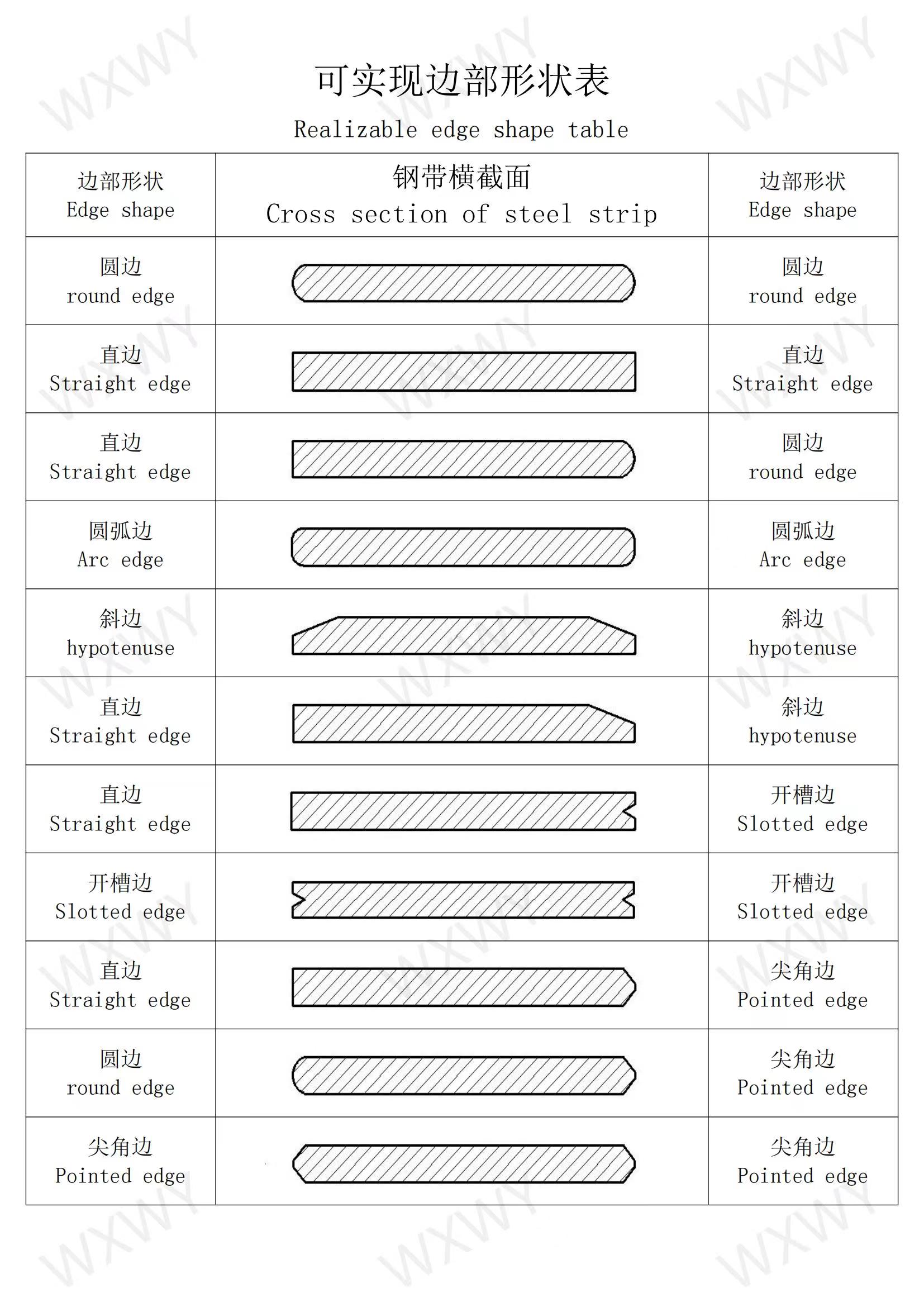

2.Finished product parameters:

Strip edge : deburring/chamfering/Round edge ,or any shap edge require from customer.

Coil Data: ID: ID:400-500 MM, OD:≤φ1200mm. width:10-150 mm. max coil weight:500kg-1000KG

3.Equipment parameters:

a.Speed:0-150M/min adjustable speed, strip trimming speed depends on material characteristics and trimming edge effect requirements

b.Power: About 50.5KW

c.Operator: 1 technician and 2-3 workers.d.Height of working: 1000 mm.

e.Space: W13*D1.5*H1.6 M.

f.Voltage:380V/ 3phrase/50 HZ(depend on customer requirment).

g.working height:1000mm

h.Knives for trimming:Each group can be equipped with 3 or 6 trimming tools, up to 24 trimming tools can be transferred

i.Scrap collection:With drawer type scrap collection box

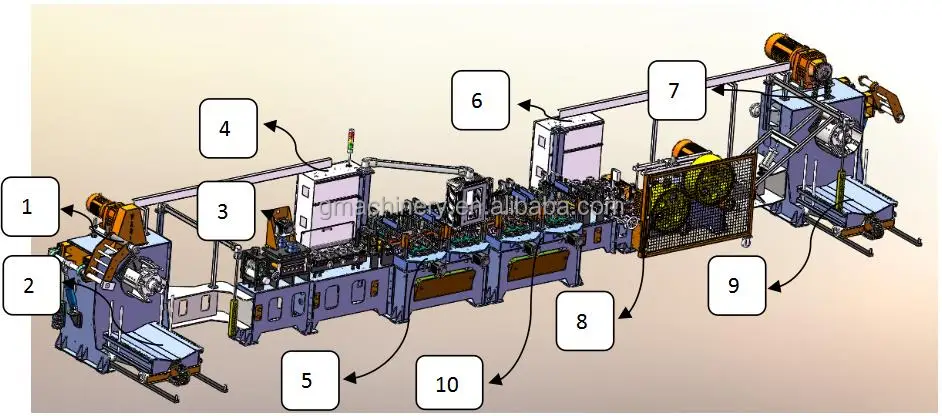

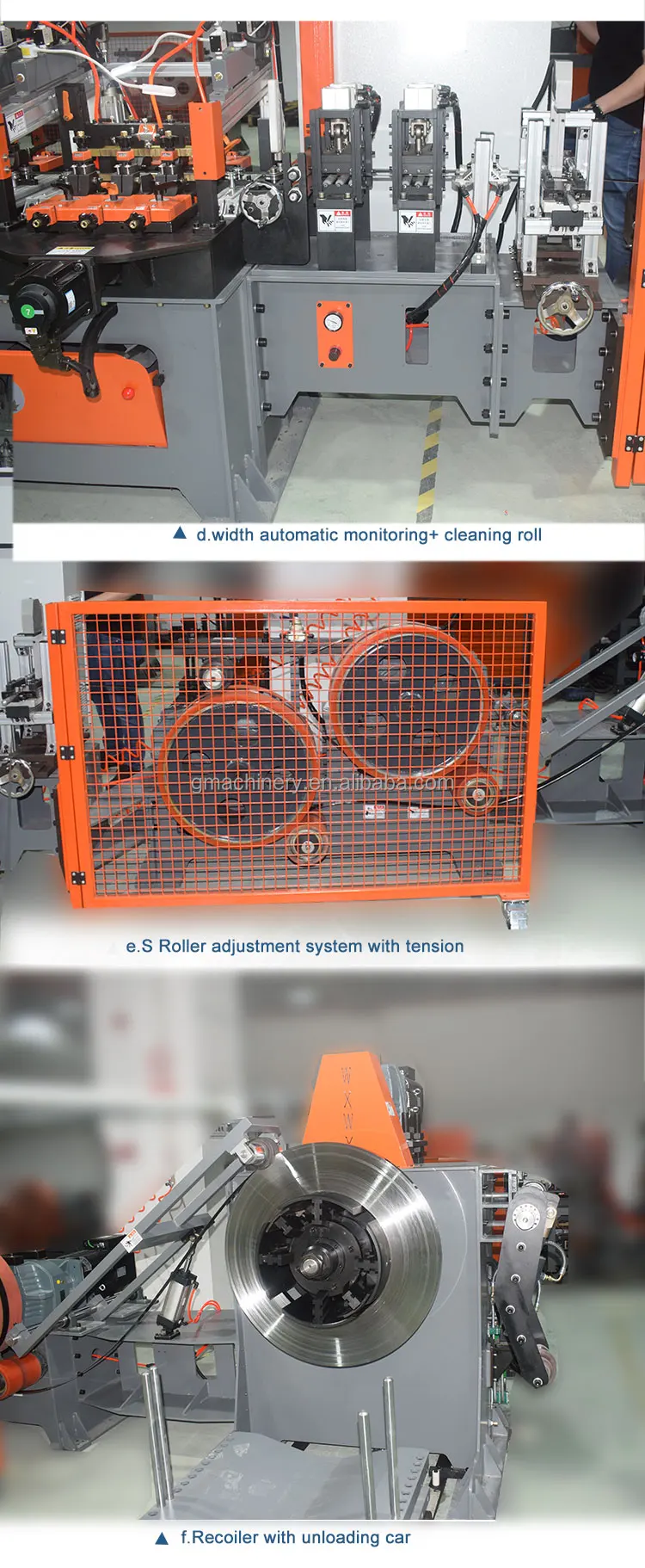

4.Equipment component

[1] Decoiler [2] loading car [3]9#servo motor

[4]2#Control electric cabinet [5] No.1#-no.4# knives [6]1# Control electric cabinet

[7] Recoiler [8] S-roll machine [9] unloading car

[10]NO. 5#-NO.8# knives

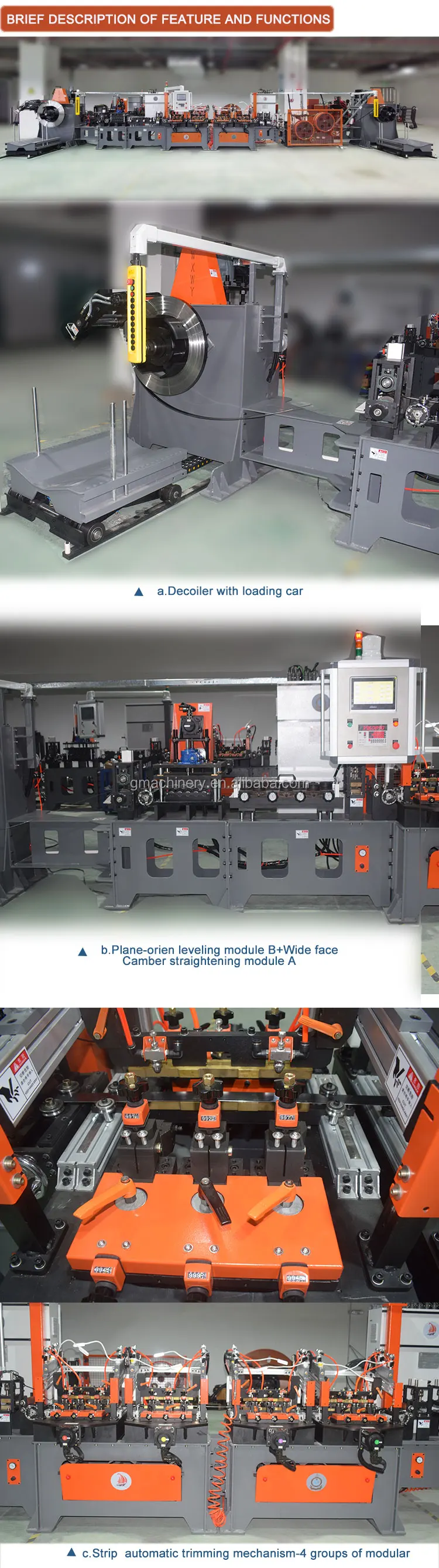

Features of the modular CNC strip trimming machine:

A.Machine Features:

1.1 When the finished product must be finished from the slitting edge to the finished edge, the quality of the slitting edge does not meet the requirements.

1.2 Glory(WXWY) modular CNC strip trimming system can prevent burrs.

1.3 Chips are removed by chip conveying system (customizable).

1.4 The surface structure of the material is not affected.

1.5 even taking into account the maximum width tolerance.

1.6 In the pipeline industry, strip trimming is essential to improve welds. –

1.7 The machining edge can be combined and carried out with the surface treatment of the strip.

1.8 Working with multiple tools/modules.

1.9 Can be integrated into existing production lines.

1.10 The cutter can be adjusted flexibly.

1.11 In the case of high speed or thick chips, a large amount of metal friction energy is introduced into the production process and converted into heat. There must be a cooling and lubrication system to reduce the heat of the tool and the processed strip, and use compressed air for cooling.

B.Modular system:

2.12 The machine/production line can be expanded modularly to increase the number of tools.

2.13 The strip trimming module and the strip surface treatment module can be combined so that two production processes can be performed simultaneously.

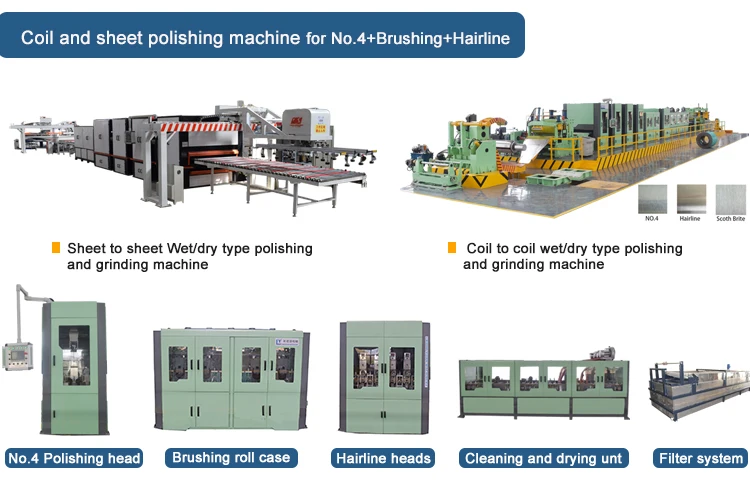

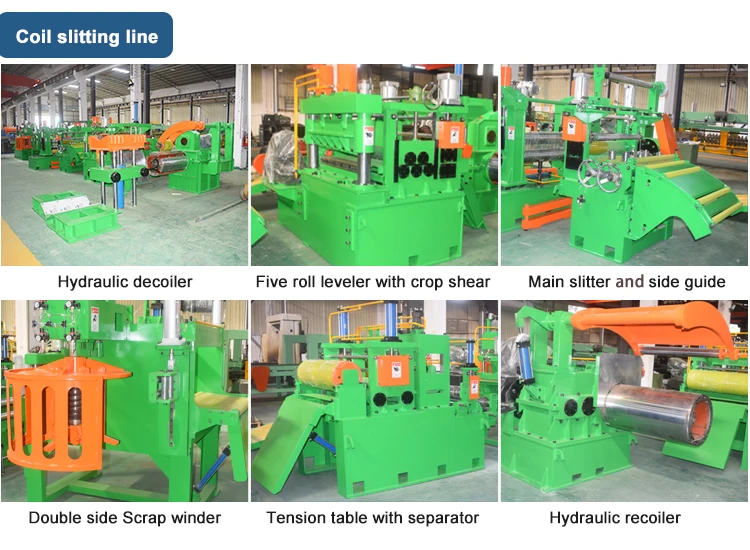

Q1: What kind of machine do you have ?

A1: We three type different machine line and accept customize

a. coil to coil wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

b. Sheet to sheet wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

c. Hi precision slitting line for cold roll for different width .

d. Cut to length (Stop shear and frying shear ) for cold roll

e. The strip edge trimming machine for deburring +Chamfering +round edge for different steel strip(from 5mm-300 mm)

Q2: How to visit your company?

Our company located in Foshan city ,Guangdong province of China , we can pick you up from Guangzhou Baiyun international airport or any other place in Guangdong province .

Q3:How long will you send the proposal and offer?

A3:We need you provide your material data and your requirement for machine,then we can give you offer within 2-3 days.

Q4: What is your payment term and lead time?

A4: We usually accept 30% deposit ( the strip edge trimming machine line need 50%), the balance must be paid before shippment ,or 70% is irrevocable LC at sight ; the lead time : we generally need about 90 days after getting deposit .

Q5: How to install the machine and the engineer fee,and warranty?

<span data-mce-style="margin: 0px; padding: 0px; border: 0px; font-style: inherit; font-weight: inherit; font-size: inherit; line-height: 24px; font-family: Calibri; vertical-align: baseline;" style="line-height: 24px

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China