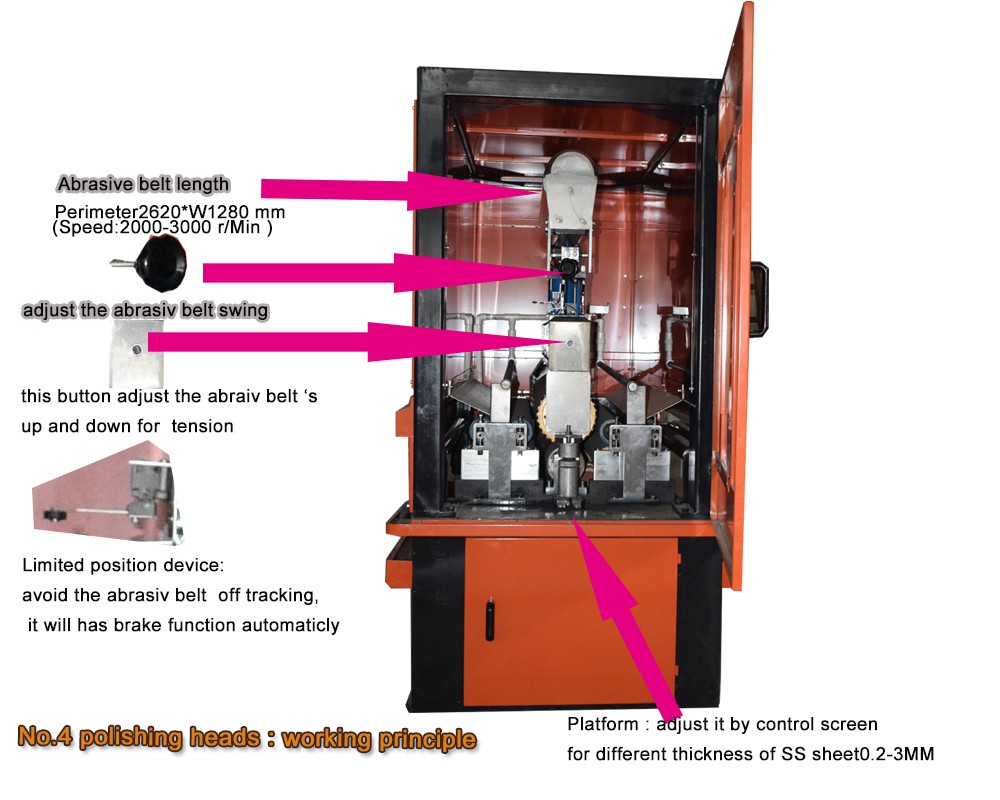

Polishing name: 1600 type Single No.4 Polishing head Proceeding Way: Sheet or coil ,Wet or dry Maximum witdh of sheet or coil: 300-1550 mm Min length of sheet: 600mm Thickness for stainless steel 0.3-3 mm( Standard) Feeding speed 0-50 M/min(Adjustable ) Main Power: 55KW+3KW transfer motor Abrasive belt length perimeter 2620*1580 mm Speed of Abrasive belt 2000-3000 R/Min Dust absorption-dry polishing: 40003/H Filter flow-wet polishing: 250 L/min Working height: sheet polishing : 920

1600 Type No.4 Polishing Machine for Top side

Technical Parameter

1.Raw material:

a.Stainless steel sheet : 430,439,445,304,316,200 series

b.Sheet surface:2B and BA surface

c.Sheet width: 200-1550 mm. max sheet: 1550*4000mm/6000mm

d.thickness of sheet:0.3-3mm.

2.Finished product parameters:

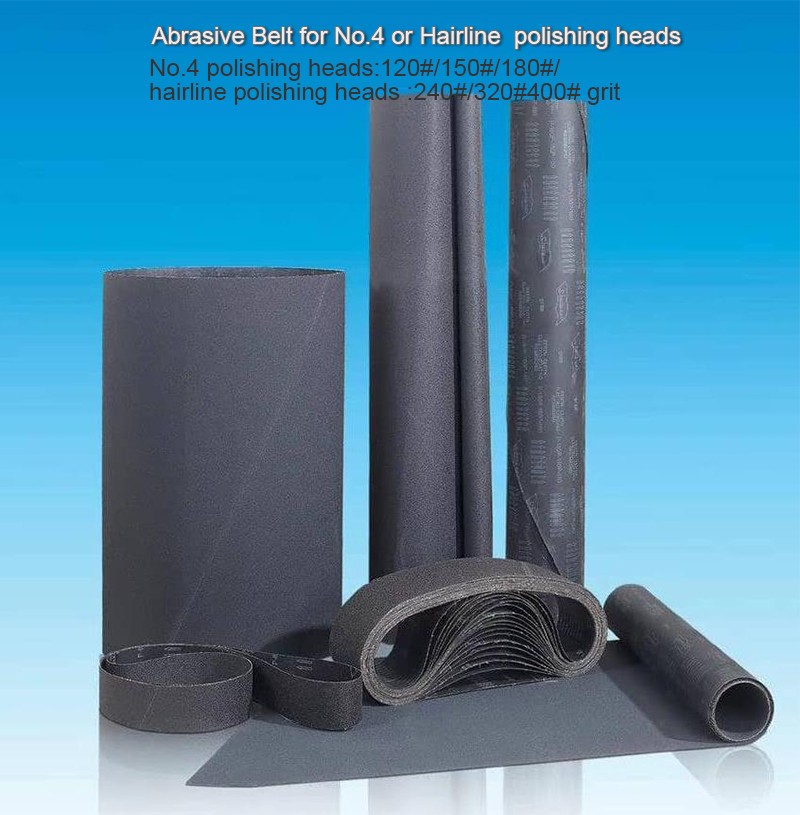

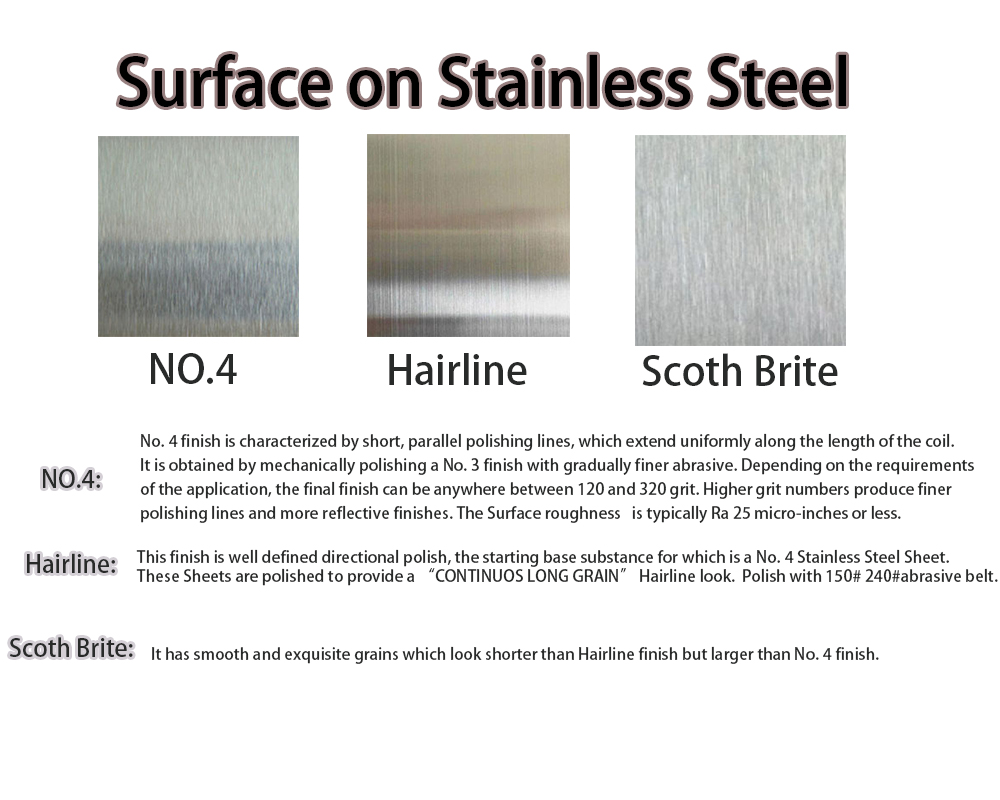

Surface of stainless steel sheet:NO.4 (dependiing grit of abrasive belt 120#/150#/180#/220#/320# grit)

3.

Equipment Description:

Single Polishing NO.4 head machine:

1. Frame: steel plate steel welding, annealing and stress treatment, large-scale gantry milling machine boring machine precision machining, side plate and stiffener plate thickness 20mm, installation combined panel thickness 30mm; bottom plate 50mm;

2. Hood: steel plate welding (color according to customer requirements);

3. Bought - out items standard parts: the fasteners are made of 304 stainless steel screws, and the bearing oil seals are imported brands and domestic famous brands;

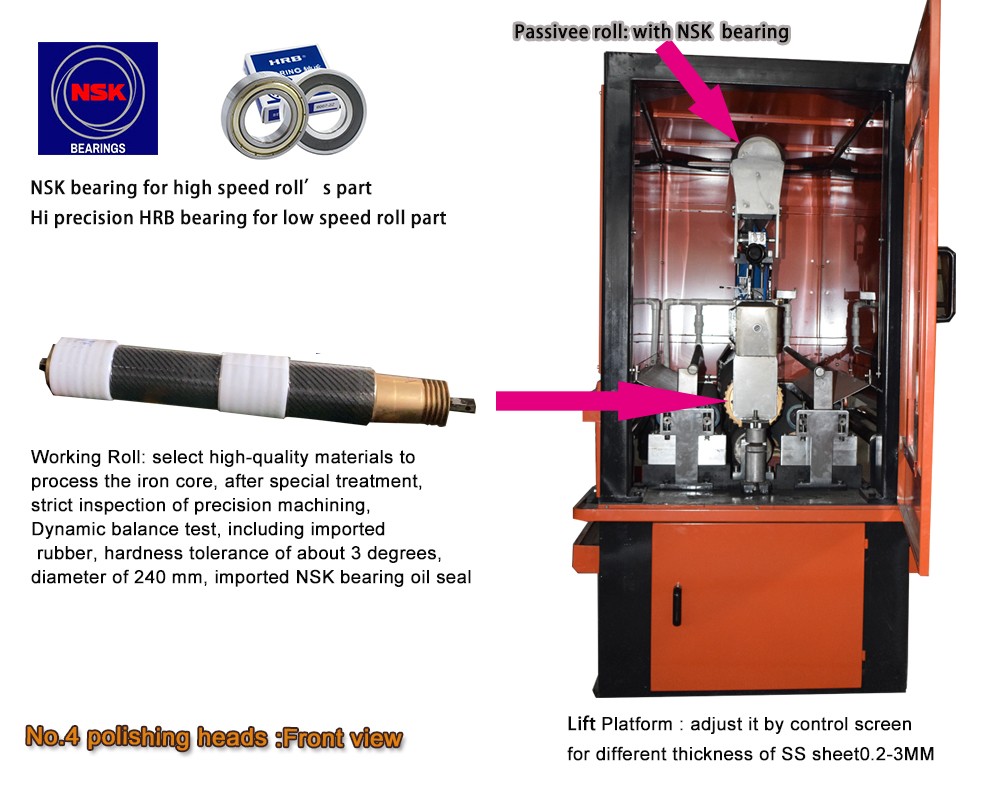

4. Sanding roller: It is made of high quality material processing iron core, after special treatment, strict processing precision inspection, dynamic balance test, including imported rubber, hardness tolerance of about 3 degrees, diameter of 240 mm, imported bearing oil seal;

5. Drive mode: motor (Jiangcheng motor), imported V-belt drive, frequency control (Shenzhen Sifang).

6. Adjustment mode: the conveyor platform is electrically lifted and adjusted to height, with digital display;

7. Bottom roller device: The material is made of 40Cr, and the medium-frequency treatment is carried out. The surface hardness is 58 degrees, the hardness layer is up to 3 mm, and the diameter is 150 mm. The height can be finely adjusted separately. The transition wheel is driven by the conveyor roller. In order to achieve the effect of synchronization with the conveying roller; the bottom steel roller can be quickly replaced.

8. Transmission conveying roller: Packing imported rubber, diameter 130 mm, roller surface 1600mm, variable frequency speed synchronous belt and worm gear reducer drive.

Q1: What kind of machine do you have ?

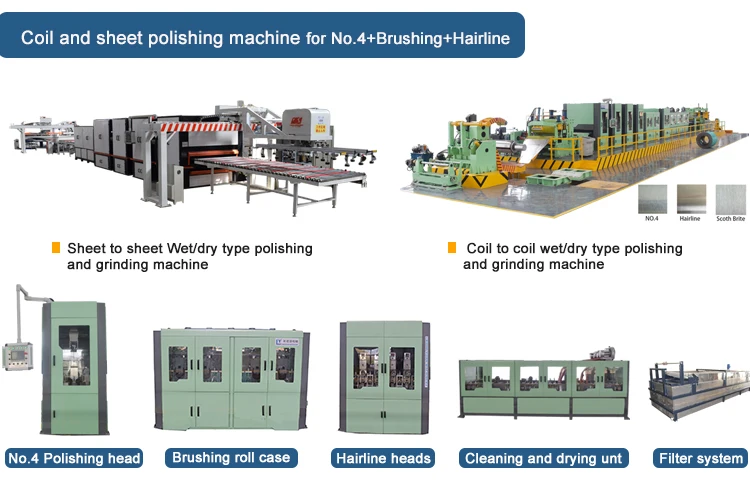

A1: We three type different machine line and accept customize

a. coil to coil wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

b. Sheet to sheet wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

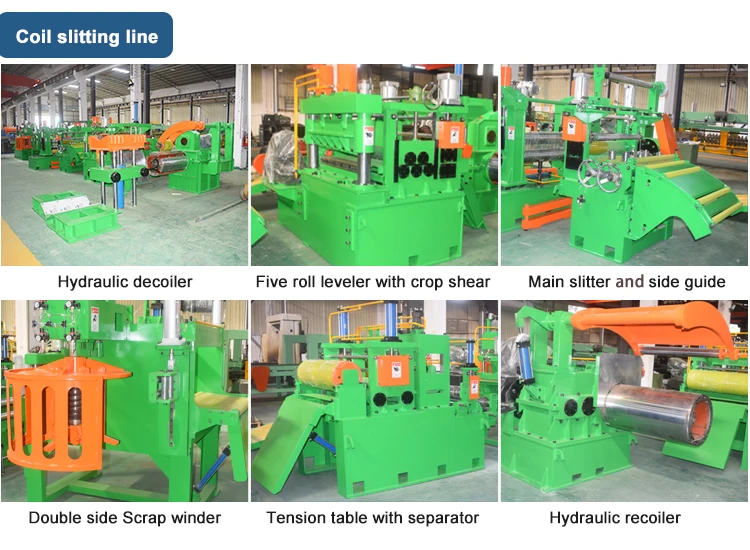

c. Hi precision slitting line for cold roll for different width .

d. Cut to length (Stop shear and frying shear ) for cold roll

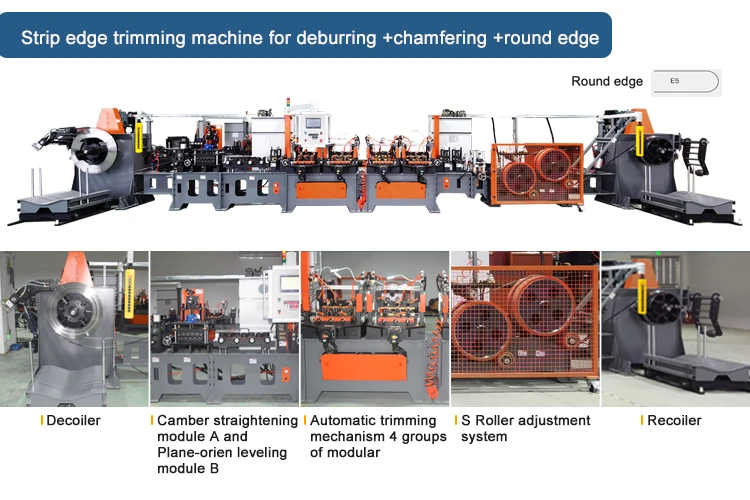

e. The strip edge trimming machine for deburring +Chamfering +round edge for different steel strip(from 5mm-300 mm)

Q2: How to visit your company?

Our company located in Foshan city ,Guangdong province of China , we can pick you up from Guangzhou Baiyun international airport or any other place in Guangdong province .

Q3:How long will you send the proposal and offer?

A3:We need you provide your material data and your requirement for machine,then we can give you offer within 2-3 days.

Q4: What is your payment term and lead time?

A4: We usually accept 30% deposit ( the strip edge trimming machine line need 50%), the balance must be paid before shippment ,or 70% is irrevocable LC at sight ; the lead time : we generally need about 90 days after getting deposit .

Q5: How to install the machine and the engineer fee,and warranty?

A5: We will send one or two engineer to install the machine in customer plant,the customer need bear the visa fee/flight ticket/accommodation during installation ,and give 80 usd subsidy to engineer; installation and training time : it usually need about 10-25 days with the cooperation from customer ,depend on the size of machine .

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China