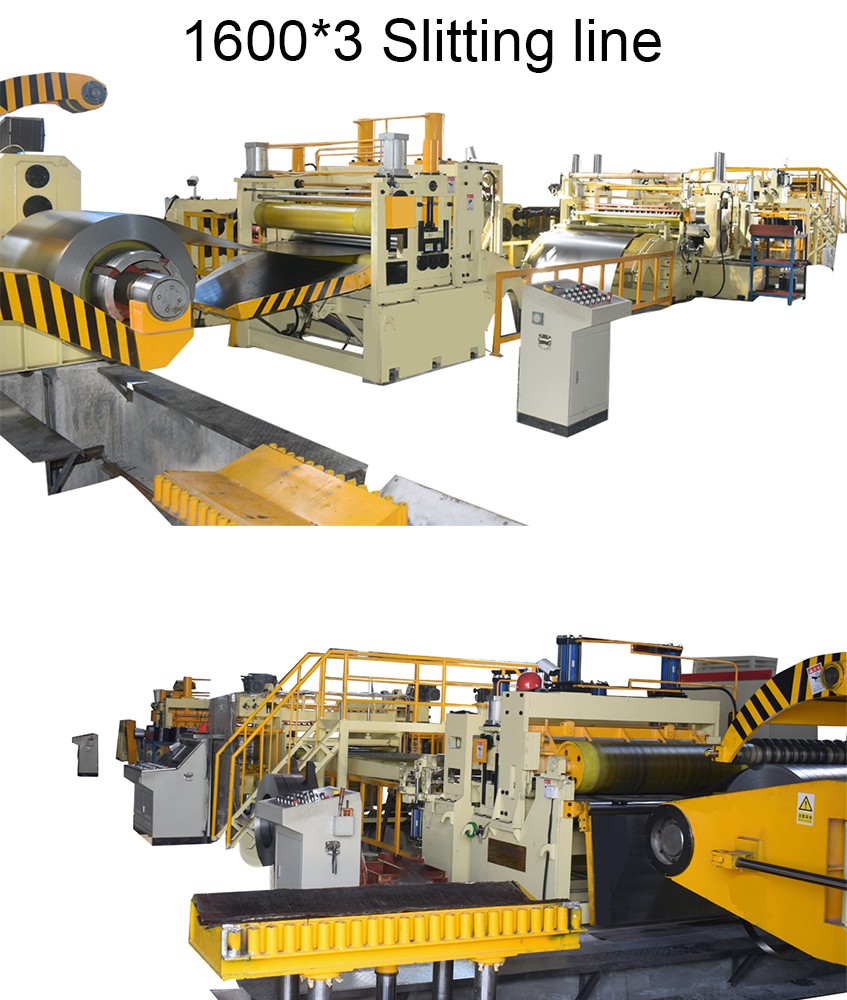

1. Product Name: 1600 type slitting line 2.Material:ss,carbon steel,galvanized,coled roll 3.ID of Coil:508 MM ,OD:≤1800mm 4.Mini width of strips:10mm 5.Scrap edge width range:2-5mm 6.Burr:≤0.05mm 7.Straightness:Strip width less 30mm: less 0.8/1M 8.Operator:1 technician and 2-3 workers 9.Height of working:1000MM 10.After-sales Service Provided:Yes

1600*3 Hi Precision Slitting Line

Technical Parameter

1、Raw material Coil:

NO. | /Name | Parameter |

1 | Coil | Cold Rolled, Galvanized Steel /HR |

2 | Thickness | 0.3-3.0 mm |

3 | Max Width | 1600mm |

4 | OD | ≤φ1600mm |

5 | ID | 508mm& |

6 | max coil weigth | 30 MT |

7 | Raw material mechanical properties | tensile strengthσb≤780Mpa |

2、Finished product parameters:

1)Strip parameter

No. | Name | Parameter |

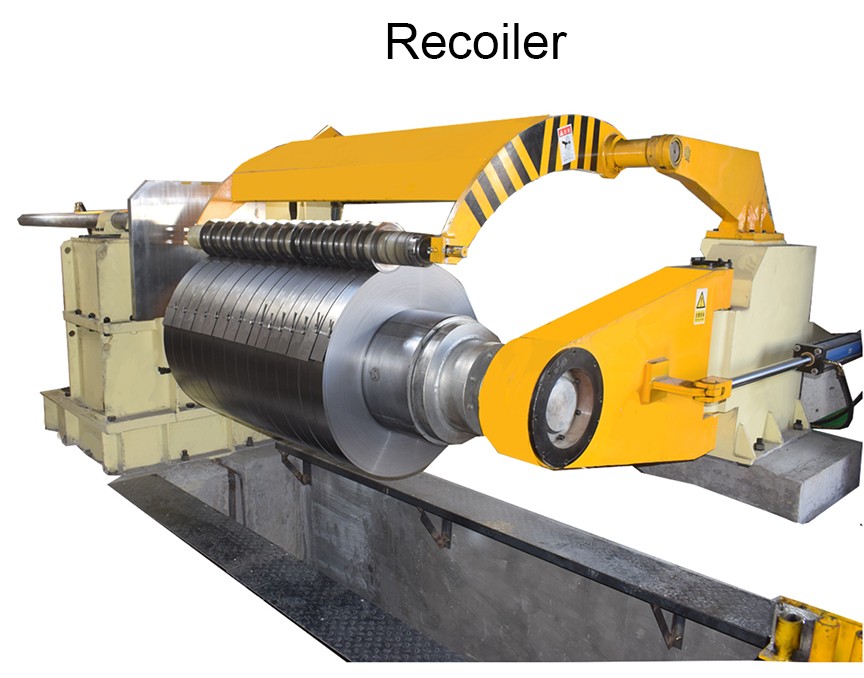

1 | Strip ID | Φ508mm |

2 | /Strip OD | ≤φ1700mm |

3 | Strips max weight | Max:20 MT |

4 | Number of strips | thickness:3.0mm≤15 pcs; 0.5 MM≤35 pcs;

|

5 | Mini width of strips | 20 mm |

6 | Scrap edge width range | 2-5mm |

7 | Burr | ≤0.05mm |

8 | Straightness | Strip width ≦ 30mm: ≦0.8/1M Width for slitting ≦30mm:≦0.8/1M Width for slitting ﹥30mm:≦0.5/1M (excluding the head and tail plates within 10M). |

2)Equipment parameters::

No. | Name | Parameter |

1 | Speed | 0-120m/min,One key to start acceleration and deceleration |

2 | Shear line speed | 0-15m/min |

3 | Power | 380V/50Hz/3Ph |

4 | Total Power | About 350Kw |

5 | Operator | 1 technician and 2-3 workers |

6 | Height of working | 1000mm |

7 | Space | (W)23m× (D)8 m |

8 | Direction | From to (The operator faces the machine , feeding coil from) |

9 | Color | according customer favor |

10 | temperature near machine | 0C-40 C |

11 | Air pressure | 0.4-0.6MPa |

3).Mechanical composition:

1.Loading car with stock bay 1 set

2.Decoiler with holding arm 1 set 37KW

3.Peel table ,Pinch Roll ,Crop shear 1 set 45 KW

4.Loop bridge1# 1 set

5.Correcting and pressing device 1 set

6.Hi precision Slitter 1 set 110 KW

7.Scrap winder 1 set

8.Loop bridge2# 1 set

9.Tension table with pinch roll 1 set

10.Recoiler with separator 1 set 132KW

11.Unloading Car 1 set

12.Supporting arm 1 set

13.Hydraulic system 1 set

14.Electronic control system 1 set

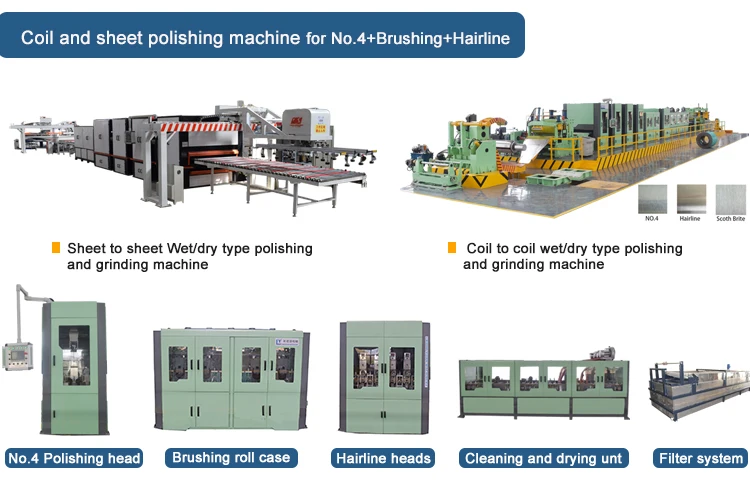

Q1: What kind of machine do you have ?

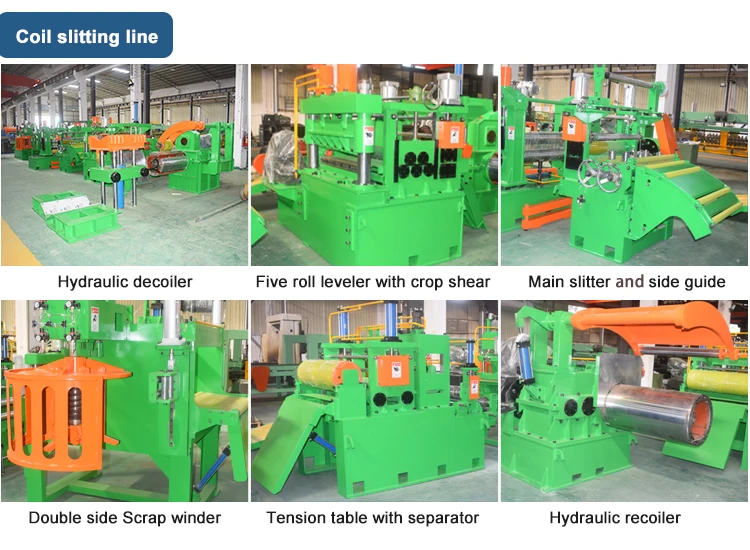

A1: We three type different machine line and accept customize

a. coil to coil wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

b. Sheet to sheet wet or dry type polishing and grinding machine for No.4 +Brushing roll+hairline for steel surface

c. Hi precision slitting line for cold roll for different width .

d. Cut to length (Stop shear and frying shear ) for cold roll

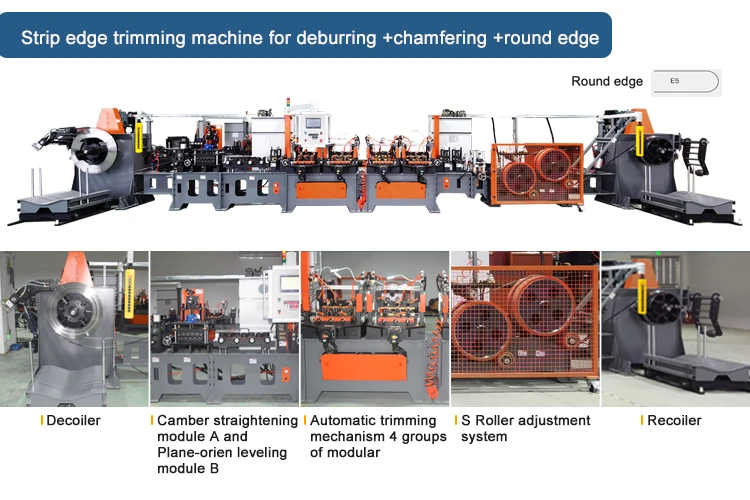

e. The strip edge trimming machine for deburring +Chamfering +round edge for different steel strip(from 5mm-300 mm)

Q2: How to visit your company?

Our company located in Foshan city ,Guangdong province of China , we can pick you up from Guangzhou Baiyun international airport or any other place in Guangdong province .

Q3:How long will you send the proposal and offer?

A3:We need you provide your material data and your requirement for machine,then we can give you offer within 2-3 days.

Q4: What is your payment term and lead time?

A4: We usually accept 30% deposit ( the strip edge trimming machine line need 50%), the balance must be paid before shippment ,or 70% is irrevocable LC at sight ; the lead time : we generally need about 90 days after getting deposit .

Q5: How to install the machine and the engineer fee,and warranty?

A5: We will send one or two engineer to install the machine in customer plant,the customer need bear the visa fee/flight ticket/accommodation during installation ,and give 80 usd subsidy to engineer; installation and training time : it usually need about 10-25 days with the cooperation from customer ,depend on the size of machine .

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China